The five human senses are marvelous, but when it comes to conducting research it is not enough to simply be able to taste, touch, smell, hear or see. For example, how can one sense stimuli or collect data in an extreme environment, such as inside a nuclear reactor? At the mouth of an active volcano? In deep space?

That’s where the ingenuity of the human mind comes in to create the perfect sensor. Generally, sensors are devices that detect or measure specific properties or events, such as light, temperature, pressure, chemicals, energy, or other inputs from a physical environment.

At Boise State University, at least 20 researchers across multiple disciplines excel at creating and perfecting sensors to advance research and push the boundaries of modern science.

Extreme Environments

Nuclear Reactors

Brian Jaques is an associate professor of material science and engineering and Boise State’s lead for the Department of Energy’s Advanced Sensors and Instrumentation Program in collaboration with the Idaho National Laboratory. According to Jaques, the vision of the program is shared among several researchers at Boise State who are working with researchers at Idaho National Laboratory.

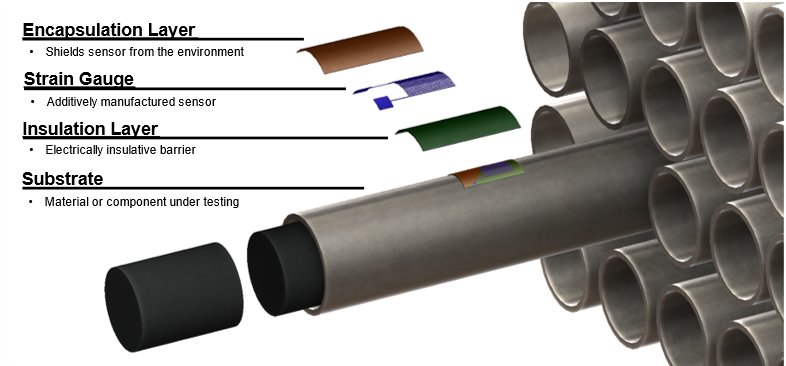

“We’re using a cross-cutting approach to model, design and develop novel sensors and materials to go into a nuclear reactor core to measure (in real-time) fundamental properties such as thermal conductivity, strain, temperature, stress and various events that are occurring like fuel cracking, the release of fission products, and elements from the reactions,” Jaques said.

Not only are these novel sensors an exciting innovation on their own, but they will create a ripple effect that enables the field of nuclear energy to advance, and hopefully combat climate change.

For example, current processes dictate that new materials or fuels to be tested in nuclear reactors stay in the reactor for a predetermined amount of time (this can be months), then are pulled out and studied for stress, strain, reactions, etc.

With the new sensors Jaques and his lab create, researchers can collect real-time data from inside the reactor, and researchers can find out much earlier if there is an issue with an experiment or material, decreasing the nuclear innovation time.

This advancement will empower safer, faster nuclear fuels testing and ultimately help get the US to its Net Zero Government Initiative goal by 2050.

Wildfires

Jeffrey Johnson and Jake Anderson, two faculty members in Boise State’s geoscience program are leaders in low-cost sensor development for infrasound (low-frequency sounds below 20 Hz) applications.

Avalanches, volcanoes, debris flows, rivers, earthquakes and wildfires make many sounds, but Johnson and Anderson know that it’s the sounds that humans can’t hear that could be the key to saving lives and taking science to the next level.

Anderson says that, surprisingly, infrasound in the context of wildfire is a fairly new frontier of research, and Anderson is leading through work conducted with the U.S. Forest Service.

In his research, Anderson develops and places sensors in an area that will undergo a prescribed burn. This preliminary research will then ideally shape methods for applying these sensors to wildfire applications.

“It’s going to be useful to map infrasound and track how and when it changes over time. The goal is improving safety; we want early warnings of dangerous changes in fire behavior to alert firefighters and others in harm’s way. These datasets could also be used to improve fire behavior models used by agencies, and that’s another way infrasound can help prevent harm from wildfires,” Anderson said.

Having that information could save the lives of fire managers, firefighters and first responders, as well as people who live in threatened areas.

This research is made possible by two grants, one for wildland fire research (U.S. Forest Service joint venture 23-JV-11111135-067) and one for infrasound sensor development (NSF award EAR-2122188).

Deep Space

With the explosion in space travel and upcoming journeys such as NASA’s Artemis Mission, the sensors that Zhangxian (Dan) Deng is making are going to be critical components to safe space exploration.

Deng is an assistant professor of mechanical and biomedical engineering, and his lab is working to create sensors that can be used on the inflatable structures that house astronauts and equipment on planets far beyond Earth.

Unlike the typical home on Earth, these structures will be at the whims of space, and even a single tear in the fabric could be disastrous.

“Inflatable structures for deep space habitats offer a lightweight, thin-walled solution, but their design leaves them vulnerable to micrometeoroids, orbital debris and cumulative creep strain,” Deng said. “Sensors in these environments must detect both dynamic impacts and static creep strain and remain foldable before deployment. My lab leverages advanced additive manufacturing to embed sensors within these structures, effectively addressing the unique demands of structural health monitoring in inflatable habitats.”

Advancing Biomedical Sensor Development

In 2024, a Boise State research team led by Professor of Electrical and Computer Engineering Jim Browning and Chemistry and Biochemistry Professor Ken Cornell received a $10.2M award from a highly competitive National Institutes of Health program to develop a center that will change biomedical capacity and sensor development for the university, Idaho and the region.

The Convergent Engineering and Biomolecular Science Center of Biomedical Research Excellence (dubbed “CEBS COBRE”) funds research infrastructure such as the fabrication, characterization and testing core for university and industry use. It also supports research project leaders like Deng, empowers new biomedical research collaborations and recruits new faculty members.

With center funding and resources, Deng’s team can continue pushing the envelope on wearable pressure sensors for biomedical applications. These flexible sensors could serve as aids in detecting conditions like Alzheimer’s, multiple sclerosis, Parkinson’s, mild cognitive impairment and musculoskeletal disorders.

Deng also works with Electrical and Computer Engineering Associate Professor Ben Johnson on the implementation of sensors that can monitor brain activity.

Another supported researcher is biophysics professor Daniel Fologea, whose work with kinetic exclusion assay (KinExA) – developed and marketed by Sapidyne Instruments of Boise – advances two kinds of sensors.

The first will enable faster detection of heart attacks. The second sensor is one that can detect and measure “forever chemicals” – or per- and polyfluoroalkyl substances – in water sources without the need for traditionally cost-prohibitive equipment.

These projects are examples of exactly what Browning and Cornell hoped Boise State would lead with the National Institutes of Health award.

“The CEBS COBRE provides opportunities for multi-disciplinary researchers to develop biomedical-related sensors that will ultimately support improved health care,” Browning said. “The funding improves Boise State University’s research capabilities through the acquisition of advanced equipment to build and test these new sensors while also giving researchers the resources to develop these sensors and to work with local industry.”

CEBS COBRE Award Disclaimer: Research reported in this publication was supported by the National Institute of General Medical Sciences of the National Institutes of Health under Award Number P20GM148321. The content is solely the responsibility of the authors and does not necessarily represent the official views of the National Institutes of Health.

- By Brianne Phillips