What if there were materials that could be produced and distributed as efficiently as current plastic, and could be easily recycled with existing infrastructure?

Micron School of Materials Science and Engineering professor Scott Phillips asked similar questions and proposed his ideas to graduate students Terra Miller-Cassman and Allison Christy. Their research in Phillips’ Macromolecular Sciences Laboratory could lead to groundbreaking discoveries with materials that are right under our noses: sugar and super glue.

Sugar

Terra Miller-Cassman became inspired to make an immediate and real-world impact after working as an environmental consultant monitoring the natural water systems in San Diego and seeing the extent of plastic waste up close.

“It blew my mind,” she said, “actually seeing it in person, quantifying, and writing reports on it just really hit home for me.”

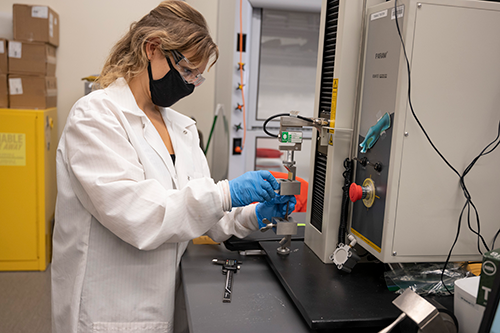

It’s been two years since Phillips proposed rethinking plastics to her. In research, Miller-Cassman found that isomalt, a sugar substitute made from sugar alcohol, when combined with certain compatible plant-based, nontoxic additives like microcrystalline cellulose, functions similarly to some plastics. Additionally, both injection molding machines and extrusion machines can process the compound. When coated with plant-based, biodegradable coatings, like shellac and cellulose acetate, the material becomes resistant to moisture and can even be submerged in water for up to eight hours without observable changes in properties. Best of all, the isomalt can be recycled several times without degradation of the mechanical properties.

Super glue

Allison Christy originally studied chemistry and political science with hopes to go to law school. But, after working with polymers during an internship with NASA and because of an interest in sustainability, she changed her educational goals and eventually started working with Phillips. She had no idea she’d end up covered in glue.

Phillips proposed ethyl cyanoacrylate, or super glue, as an alternative starting material. She found that heating the polymerized super glue to the right temperature allowed the material to become soft and malleable and easy to shape into objects. When it cools, the material resembles polystyrene, which is one of the least recycled types of plastic. A bowl they created with the super glue material was able to hold water for seven days without changes in its physical or mechanical properties. While polymerized super glue forms a robust plastic, it is not petroleum based and it can easily break back down to a monomer through a mild heating process making it more recyclable than polystyrene plastic.

Closing the loop

Both Miller-Cassman and Christy envision their alternative materials replacing the polymers used to make single-use products like cutlery, bowls, plates and cups. They are easy to produce and can be recycled in a closed-loop process. The potential of these materials is yet to be fully discovered, but with innovative minds it may be the kind of alternative needed to challenge the plastic waste crisis.

-by Ally Bea Smith