Healthcare workers across the country are running out of personal protective equipment (PPE) due to the COVID-19 pandemic. As a result, items that were intended to be single-use PPE are now being reused over and over. Uwe Reischl, a professor in the Department of Community and Environmental Health, teamed up with local companies Obtainium Science and Industry Surplus and Reuseum Educational Inc. to develop a solution for frontline workers that could also keep the general public healthy and safe.

“It all started by a common goal, to serve the community and address the needs of individuals and families,” Reischl said. “Something that would be affordable and require zero technical expertise.”

Their solution: ozone. While it might seem surprising to most people, using ozone to destroy microorganisms or bacteria is not a new concept, according to Reischl. It has been used for a century to sterilize foods (primarily fruits, vegetables and meats), protective clothing, airplanes and houses. As a gas, it can reach areas other sterilization methods can’t, it doesn’t produce any residues and is relatively safe at low concentrations.

For instance, ozone fumigation is used to sanitize airplanes, buses, and rental car interiors. Some hospitals add it to their laundry, because ozone is known to kill C. diff, MRSA, staph, and other viruses, bacteria, and germs on contact.

The team decided ozone would make an ideal PPE sterilizer.

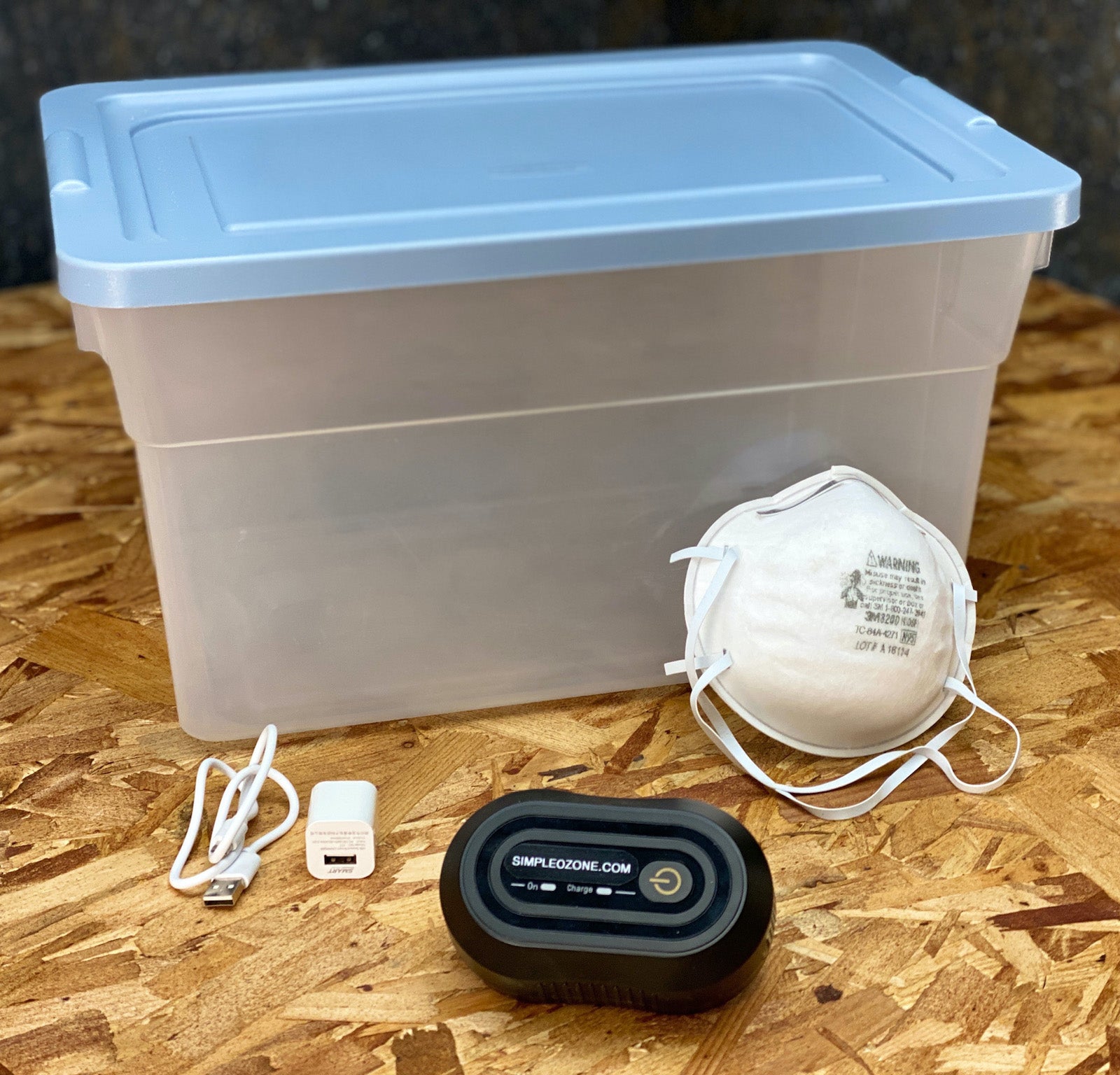

They developed an easy-to-use, portable and affordable model for a sterilization kit they call the “Simple Ozone Sterilizer.” The model is battery-powered and can produce ozone in seven minutes. The method is composed of three accessible components that cost under $100 in total: a small, battery-powered ozone generator, a charging device and a seven-gallon (27-liter) sealable, plastic storage bin.

It’s a method that nearly anyone or any hospital can create on their own without any technical expertise (a complete guide and instructions can be found on the Simple Ozone Sterilizer website).

“This method is exceptionally simple, incredibly inexpensive and could be a real game changer in terms of saving lives,” said John Schiff, another of the protocol’s developers. “It only takes an hour compared to 24 hours like some other solutions, allowing for multiple cycles in one day. It doesn’t require water, and it can be deployed anywhere in the world – even in small, remote villages – as long as you have a cell phone charger.”

By keeping the volume small in a plastic storage bin of this size, the ozone will dilute in the air as soon as the lid is opened, making it safe for individuals to use. If more face masks needed to be sterilized at one time – like 20 to 40 masks – it would require a larger container to be set up outside. This method is only recommended if someone has the proper expertise or guidance from the Simple Ozone Sterilizer team.

An opportunity for this method to be applied in a much larger capacity may come this summer. As hundreds of students and their families are expected to visit the Boise State campus in the coming months, each of them likely will be required to wear masks when doing so. Reischl is confident the process can be applied to disinfect the visitors’ masks each day while they spend several days on campus.

“We know we can do it,” he said. “We’ll scale it up.”

The companies involved will not be selling or producing any of the kits, but rather making the information available as a public service for those all over the world. One of Reischl’s colleagues in Kenya already is sharing the protocol with hospitals there.

“I believe this is what universities are supposed to do, in addition to teaching and producing research,” Reischl said. “We provide community services. And this is an example of a community service project that has immediate and important implications to protect the public from the coronavirus.”Uwe Reischl