Salt, water, car batteries and some chemistry know-how from a Boise State alumna recently came together to create a homemade disinfectant and help keep an orphanage in Mwanza, Tanzania, safe from COVID-19.

“With the rapid approach of the virus, the community was in desperate need of sanitation products,” said Ann Larson (BS, chemistry, ‘96), who has been consulting remotely with the orphanage. “Working with the director, Jerald Malamba, we taught the community how to make bleach and to ensure the proper safety precautions were followed.”

“The process is fairly simple,” Larson said.

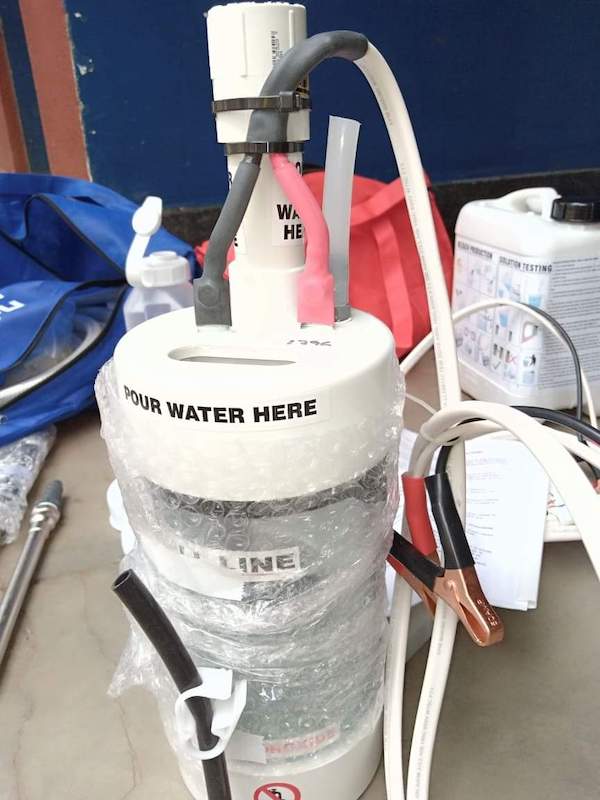

A solution of dissolved salt (sodium chloride) is placed in a container with a positive electrode at the bottom and a negative electrode at the top. The chloride ion is negatively charged and when an electric current is applied, is attracted to the positive electrode. The chloride ions pair up to form chlorine gas, which bubbles through the solution and forms sodium hypochlorite (bleach) in this alkaline environment. The orphanage uses a car battery to supply the electrical current.

The bleach is used as a disinfectant in a multitude of ways: hotels, schools, hospitals and homes use it as a cleaner and sanitizer for surfaces, and in a diluted form for hand cleaning to prevent the virus’ spread. The product is the same as bleach one would buy at a store, just produced in much smaller quantities.

The product is sold through a local network of volunteers; each of them walks in a different direction for distribution. Although walking on foot helps the volunteers build relationships with the villagers, it is a time-consuming process. Few people are reached in a day.

“A motorbike or other vehicle would improve the distribution,” Larson said. “We are in the process of applying for grants and matching funds to improve in this and other areas.”

The other limitations facing the production are storage and the power source used to create the bleach.

“The bleach is being sold as fast as it can be made, so we have not needed long-term storage for that, so far,” Larson said. “But the interest in this project has grown tremendously and the demand is huge compared to the equipment we have at hand currently.”

During her time at Boise State, Larson competed in cross-country and track and field. Numerous injuries curtailed her ability to compete and she was finally diagnosed with severe rheumatoid arthritis before her senior year.

“I was fascinated by the remarkable effect the prescribed drugs had on my health, allowing me to regain full strength and mobility,” she said. “This led me to a senior research project involving rheumatoid arthritis and subsequent research in other types of pharmaceuticals. I’ve now spent most of my career in analytical chemistry, testing and researching pharmaceuticals. I am grateful to Boise State for my excellent instruction in chemistry, and especially for my adviser, Susan Shadle, who encouraged my independent research.”

Now, as production scales up in Mwanza, the community also sees the need for a larger power source.

“We started this project on a small scale, using car batteries to provide the electricity, but now we see how much we could benefit from a generator to increase production,” Larson said.

Most of the profits made so far have gone to feed the children of the orphanage but the organization is looking to reinvest in the operation and in other public health projects.

“We use the same equipment for water purification as for bleach production so we are looking to get several large tanks to store the purified water, as well as purchasing more containers for bleach distribution,” Larson said.

Larson sees a potential benefit in this operations’ ability to expand community training in areas such as hand washing and general COVID-19 awareness.

“We used some of the profits to print stickers in Swahili and those are being put on washing stations throughout the community, reminding people to frequently wash their hands to reduce the spread of the novel coronavirus,” Larson explained.

– By George Thoma