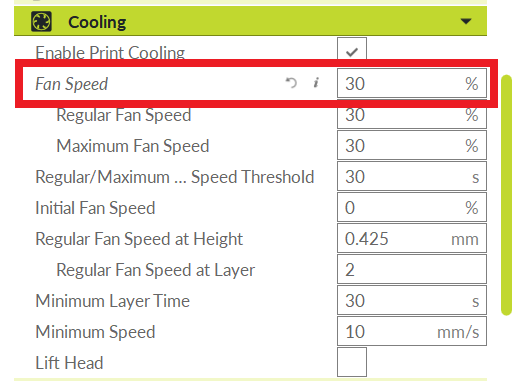

Cooling sets how much the fans cool the nozzle and plastic being deposited. For our printers, you only need to change cooling settings if you are using an aerostruder. Printers with a regular extruder, or a SE .5mm extruder, work fine with cooling at 100%, which is default. An aerostruder is a different type of extruder and requires different cooling settings. For aerostruders, the cooling needs to be set lower than normal. This is because the aerostruder will cool the print off too fast throughout the length of the print if left at 100%. To change this, change the “Fan Speed” option under the cooling tab to 30%. This will update all the other fan speed options. Too much cooling can cause your print to warp on the edges, peel up off the bed, or cause the layers to not adhere well to each other.