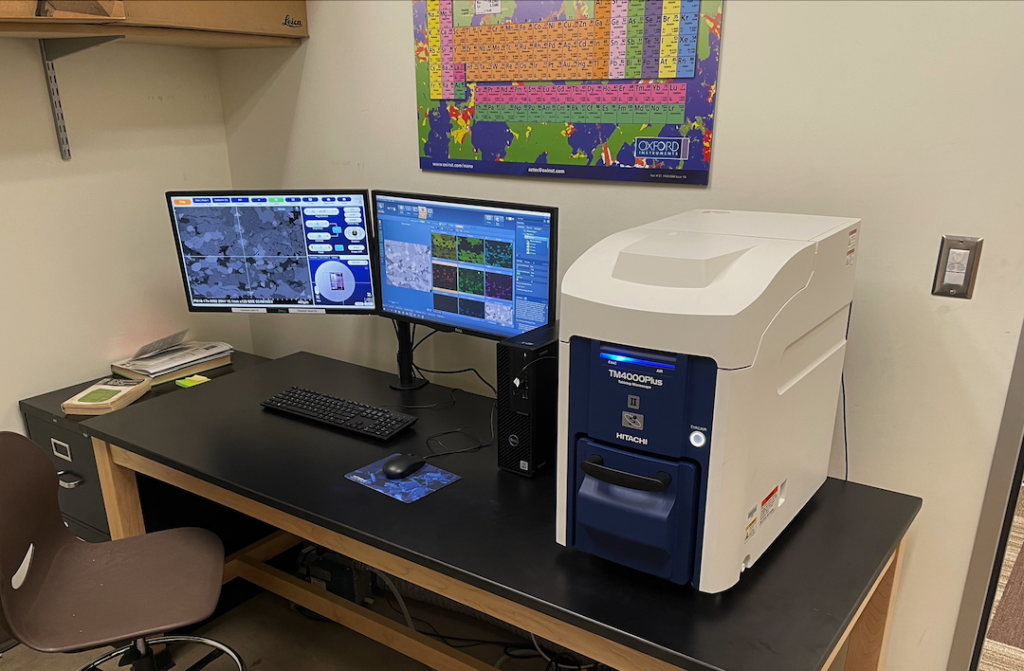

The IGL maintains its own Hitachi TM4000PlusII table-top scanning electron microscope outfitted with motorized stage, a four-quadrant back-scattered electron detector, a unique low vacuum secondary electron (SE) – cathodoluminescence (CL) UVD detector, and Oxford Instruments XploreCompact 30 energy dispersive X-ray spectroscopy (EDS) detector with Aztec analysis software. This combination of detection systems allows for high-resolution imaging as well as semi-quantitative major element analysis of both uncoated and carbon-coated thin sections and mineral grain mounts.

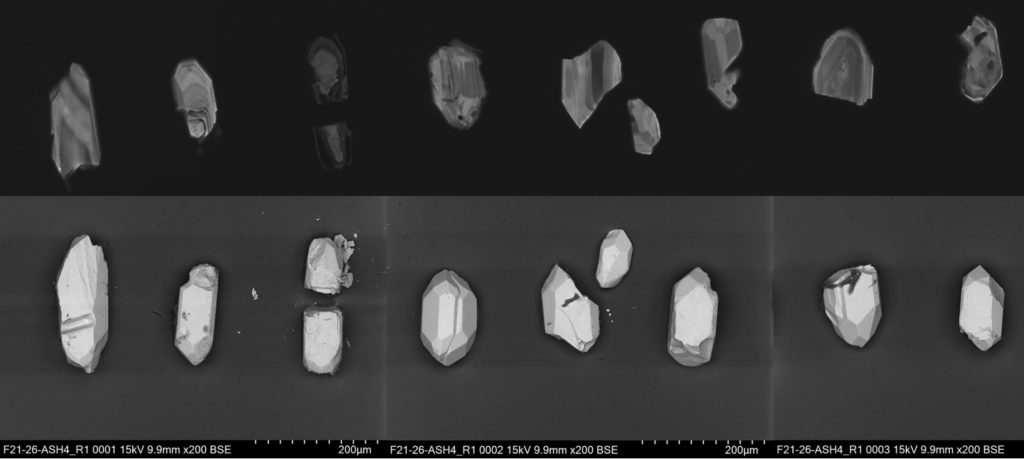

Although the UVD detector doesn’t have a light guide like traditional CL detectors, the ability to automate relatively slow scans through the Hitachi ZigZag large area function and motorized stage allows high quality CL imaging of zircon at 20 kV accelerating voltage and maximum beam current. The four-quadrant BSE detector and charge reduction vacuum mode allow us to characterize zircon surface features in unprecedented detail, useful for examining possibly reworked tephras.

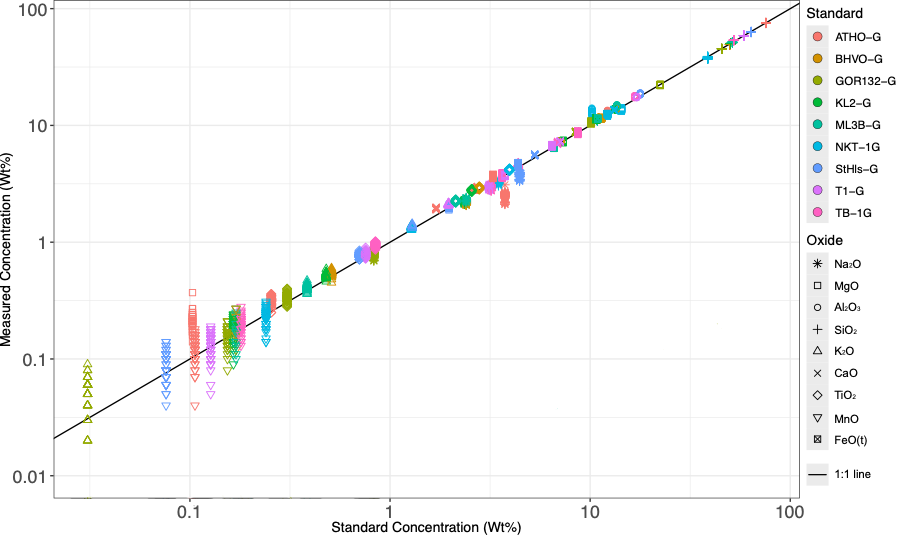

The ability to operate at 20 kV accelerating voltage makes the integrated Oxford EDS detector and Aztec software a fully functional tool for semi-quantitative to quantitative compositional analysis using energy dispersive X-ray spectroscopy. Shown below are the results of analysis of glass standard reference materials.

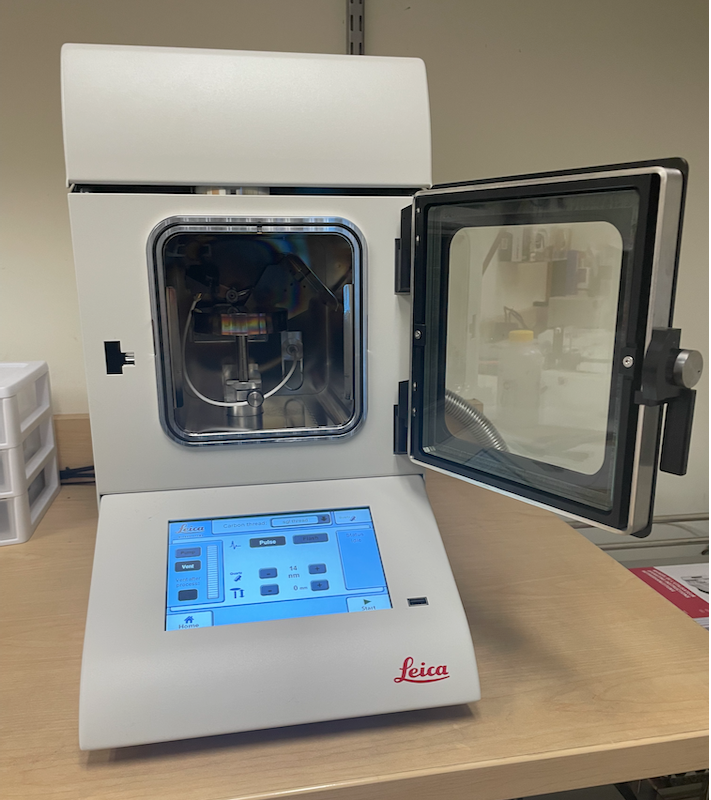

Our most recent acquisition is a Leica ACE200 carbon thread coater with quartz thickness monitor. This carbon coater is fully automated from pumpdown to coating and venting, and the quartz thickness monitor provides highly reproducible coating at nanometer resolution. This allows much more reproducible CL imagery due to the uniformity and thinness of the carbon coat we can deliver to the mount surface.