Team SOKT

Garrett Auby, Preston Bellville, Matthew Walsh, Aaron Weeks

Building a better prosthetic. Here on team socket we’re working towards helping amputees by building a prosthetic that fits right all the time. This device will ideally help amputees by improving their quality of life. When someone has an amputation their way of life changes completely. They can no longer do the things they want to when they want to.

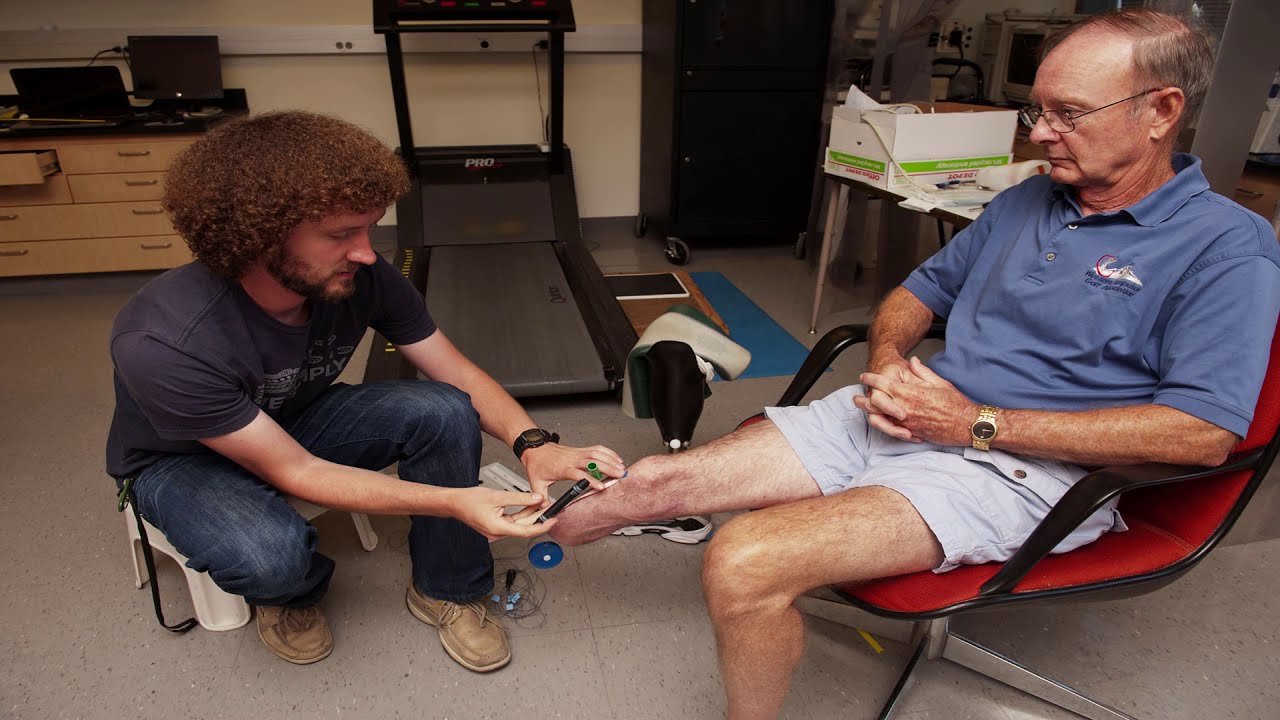

One challenge that new amputees and existing amputees have is finding the best fit for their prosthetic. Throughout the day amputees often see a decrease in the volume of their limb which affects the fit of their prosthetic socket.

Having a prosthetic that doesn’t fit right causes more than just discomfort. It can cause pain, bruising, and sometimes bleeding. In some extreme cases patients can even lose the ability to balance correctly on their prosthetic leg.

Currently to accommodate for volume change amputees need to stop what they’re doing in the middle of the day, take off their prosthetic leg which often involves taking off their pants, and put more socks on their residual limb. Applying more socks is a cumbersome activity for anybody that has to do it you know five, six times a day every day for their life.

Here on team socket we built a socket that automatically senses for volume change and tightens accordingly. Our team is able to adjust the socket to the volume of the patient’s residual limb by measuring the pressure internally and applying a tightening force to the outside.

Our group has really been given an opportunity to actually help someone out here. The device will collect data throughout the day and adjust itself accordingly to compensate for any volume fluctuations.

[Music]

This device gives amputees much more freedom in their day-to-day lives than traditional prosthetics.

We redesigned the current market standard for tightening in prosthetic sockets and made it automatic. Using pressure resistors located on the inside of the socket, we’re able to monitor the volume fluctuations through an arduino board and control a worm geared motor that can tighten or loosen specific panels inside the socket.

If we can increase the quality of life of someone by just a little bit then i believe that this project was successful.