A novel method of reducing contamination on production of filter cores

Porvair is working on innovating various aspects of their manufacturing processes in order to better accommodate the needs and requests of current and future clients. In regards to this, Porvair has offered a project to a talented team of future mechanical engineers at Boise State University in order to provide them with a viewpoint of a real world engineering project. The project explores analyzing a current manufacturing operation and developing a set of process improvements. Porvair requests a device to automate aspects of the process, thus reducing contamination and improving on the production rates of Porvair’s filtration products.

The Team

Members

- Nigel Booth

- Scott Buchanan

- Ryan Caldwell

- Hayden Golay

- Terek Zimmerman

PTFE filter wrapping and sealing machine

A novel method of reducing contamination on production of filter cores

Executive Summary

Certain information has been redacted to preserve intellectual property while still presenting the student project.

Porvair is working on innovating various aspects of their manufacturing processes in order to better accommodate the needs and requests of current and future clients. In regards to this, Porvair has offered a project to a talented team of future mechanical engineers at Boise State University in order to provide them with a viewpoint of a real world engineering project. The project explores analyzing a current manufacturing operation and developing a set of process improvements. Porvair requests a device to automate aspects of the process, thus reducing contamination and improving on the production rates of Porvair’s filtration products.

Problem Statement

Porvair is a company who specializes in high-quality filtration products. [Redacted]

[Redacted]. A device is desired to automate aspects of the process to reduce human interaction, thus reducing contamination and improving on the production rates of Porvair’s filtration products.

Safety Regulations

OSHA Standards

1. OSHA Standard 1910.94

- www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.94

- This OSHA standard covers workplace ventilation needs.

2. OSHA Standard 1910.212

- www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.212

- This OSHA standard covers shielding in machinery and how it should be used to protect the operator.

Safety Data Sheets

- [Redacted]

- [Redacted]

Benchmarks

Item Name: Bag Sealer (Food Application)

Device addresses one of our issues – the application of a linear thermal seal. Could have useful info on heat application, pressure, etc.

Pros:

- Very similar to one of the operations in the manufacturing process

- Simple and straightforward

Cons:

- Doesn’t address wrapping or circumferential seals

- Heated surface degradation

Item Name: 3D Printer Hot End

Investigating the methods used for precisely controlling the temperature of the extruder hot end on a 3D printer could yield methods applicable for controlling the temperature of our sealing surfaces.

Investigating the methods used for precisely controlling the temperature of the extruder hot end on a 3D printer could yield methods applicable for controlling the temperature of our sealing surfaces.

Pros:

- Model for active temp control

- Common enough for numerous solutions and approaches

Cons:

Precise and/or active temp control may not be necessary

Item Name: Bottle Cap Induction Seal

Induction Sealing Machine: The Ultimate Guide

While our method of applying heat will very likely be different, some other properties such as pressure applied or materials used may be relevant.

Pros:

- Very similar application – seal applied thermally

- Pressure applied during sealing process

- Analogous materials

Cons:

- Very different heat source, very unlikely we will use induction

Item Name: Tape Dispenser, Various Types

www.mcmaster.com/packing-tape-dispensers/

Tape dispensers of various designs could inspire designs for cutting and wrapping methods.

Pros:

- Designs could have insight for wrapping and cutting mechanisms

- Relatively simple, compact

Cons:

- Tendency to jam/break

- Not “clean” cut edges

Background and Problem Analysis

1. Customer Stated Values

- Major goal is to reduce the amount of human touch points to a minimum, ideally to 3 or less

- Budget should be kept at a minimum, ideally less than $500.

- Must not contaminate the filter or create large divots that can negatively impact the filter.

- Operated by a single technician

2. Limitations of using Existing Materials

- For the safety of the operator, the temperature of the [Redacted] film must be maintained [Redacted] [Redacted]. Higher temperatures, [Redacted] may release toxic fumes.

- Max Tension for [Redacted] is [Redacted], [Redacted]. The thickness and width of tape rolls is needed to accurately predict this.

- Pressure, geometry of heating element, and rotation mechanism should not tear or damage the [Redacted] film

3. Benchmark Values

The amount of cuts and heat seals will be the same but will be more accurate and consistent.

Stakeholder Analysis

Operator/Person Wrapping Filters

- Safety of Device

- Usability

- Simplicity

- Consistency

Porvair

- Production rate

- Production quality

- Operational cost of device

- Capital cost of device

- Consistency/up time

- Sales, acquiring new customers

Customers

- Safety of Filter

- Performance

- Consistency

- Lifespan

- Costs

Repair technicians

- Safety while maintaining/repairing

- Ease of maintenance

- Availability/Documentation of parts

Engineers designing future improvements

- Availability of documentation

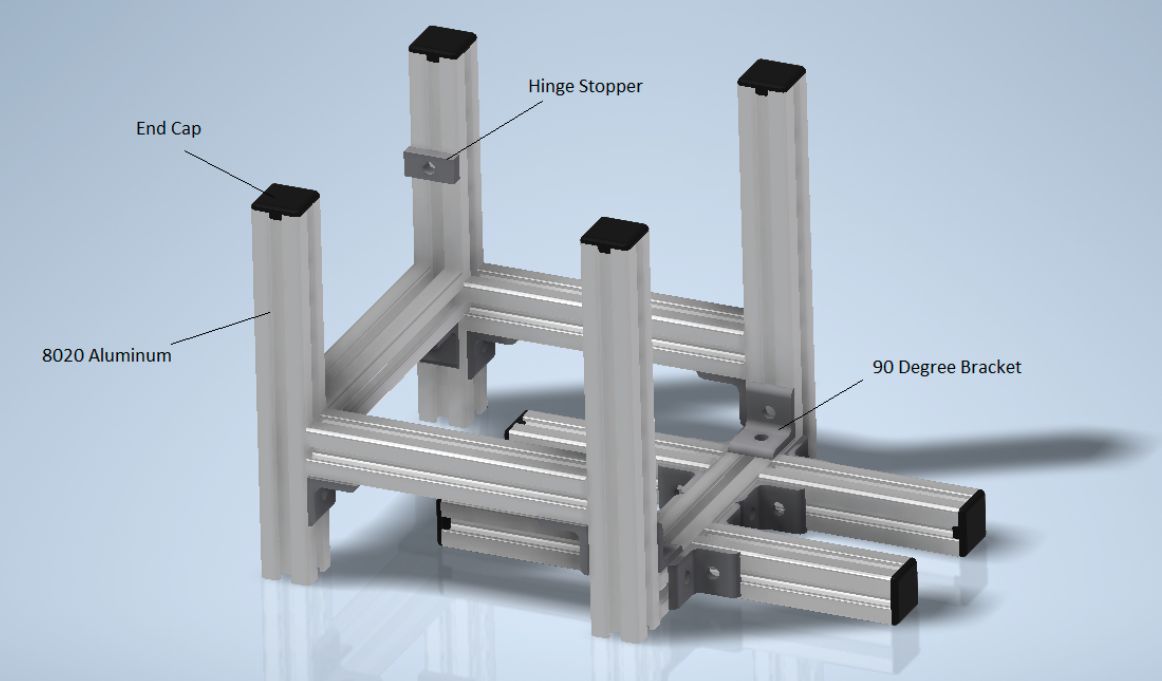

- Modularity

Needs

| Need # | Description of Need | Justification | Required (Y/N) |

|---|---|---|---|

| 1 | Proper containment/protection for the operator by avoiding pinch points, hot surfaces, and [Redacted]. | OSHA Requirement 1910.212 | Y |

| 2 | Operating conditions do not induce pyrolysis of [Redacted]. | [Redacted] | Y |

| 3 | All contact surfaces do not contaminate the membranes with unneeded patriculates or oils. | General Info Handout, See Bullet 4 | Y |

| 4 | Accurate contact temperature, pressure control and contact duration for a successful seal. | General Info Handout, Bullet 2, 5 | Y |

| 5 | Must be able to seal circumferentially as well as longitudinally. | General Info Handout, Number 2 | Y |

| 6 | Minimize excess [Redacted] flap after sealing longitudinally. | General Info Handout, Number 3 | Y |

| 7 | Sealing and Wrapping operations require minimal human touch points with the use of automation while speeding up production. | Customer stated requirements, see Bullet 1 | Y |

| 8 | Accurate indexing of filter to ensure that the same spot will be heated once the filter has gone through a full revolution. | General Info Handou, see Bullets 4 and 6 | Y |

| 9 | Operated by a single technician with limited technical background. | Customer stated requirements, In person conversation | Y |

| 10 | Be able to easily fix and maintain the device with minimal hand tools and instructions(Intuitive to maintenance personnel). All parts should be easily accessible. | General Info Handout, Bullet 3 | Y |

| 11 | Function with [Redacted] sizes of filters. | General Info Handout, Bullet 8 | Y |

| 12 | Function with [Redacted] sizes of membrane spools. | Customer stated requirements, Bullet 7 | Y |

| 13 | New wrapping process is as fast or faster than a technician performing the same process by hand. | Customer Desires, In Person Conversation | Y |

| 14 | Includes mounting positions for multiple spools for fast switches of materials. | General Info Handout, Bullet 7 | N |

Specifications

| Spec Item | Related Need # | Specification | Justification and Reference | Required Y/N |

|---|---|---|---|---|

| A | 1,2,4 | Heated tip temperature is less than [Redacted] | Background and Problem Analysis, Limitations of Using [Redacted], Bullet 1 | Y |

| B | 1 | Guarding in place to protect the operator from pinch points and hot surfaces accessible from the point of operation. | OSHA Standard 1910.212 (See Standards and Regulations) Shielding must be in place to protect the operator from machine parts. | Y |

| C | 3, 4, 5, 6 8 | Filter should be effective when the wrapping and sealing process is completed. | Background and Problem Analysis, Benchmark Values, Bullet 1 | Y |

| D | 3, 7 | Wrapping process can be completed with as few human touch points as possible, ideally 3 or less. | Excessive human contact can contaminate the membranes. Background and Problem Analysis, Customer Stated Values, Bullet 1 | Y |

| E | 3 | No parts of the machine can contaminate the membrane. | Background and Problem Analysis, Customer Stated Values, Bullet 1 and 6 | Y |

| F | 4 | Contact force does not induce large divots into the core or membrane. Small divots are acceptable. | Background and Problem Analysis, Customer Stated Values, Bullet 6 | Y |

| G | 11 | The device will accommodate various filter cores. | Background and Problem Analysis, Customer Stated Values, Bullet 4 | Y |

| H | 6, 13 | Production rate exceeds [Redacted] work day. | Tool’s use is to increase production rate and reduce contamination. | Y |

| I | 8 | Operated by 1 technician | Background and Problem Analysis, Customer Stated Values, Bullet 7 | Y |

| J | Project spending should be at a minimum, ideally $500 or less. | Background and Problem Analysis, Customer Stated Values, Bullet 5 | Y | |

| K | 12, 14 | Accommodate various spools of filter media. | Background and Problem Analysis, Customer Stated Values, Bullet 8 | N |

Form and Function

Analysis of Performance

| Sub-System | Advantages | Disadvantages |

|---|---|---|

| Rotating Heating Elements |

|

|

| Guide Slots for Longitudinal Seal |

|

|

| Handles/ Hand Crank |

|

|

| Filter Fixturing |

|

|

| Loading/Unloading Bolt |

|

|

| Tape cutting assembly |

|

[Redacted]. |

| Heating Elements |

|

|

Testing and Performance

Spec A

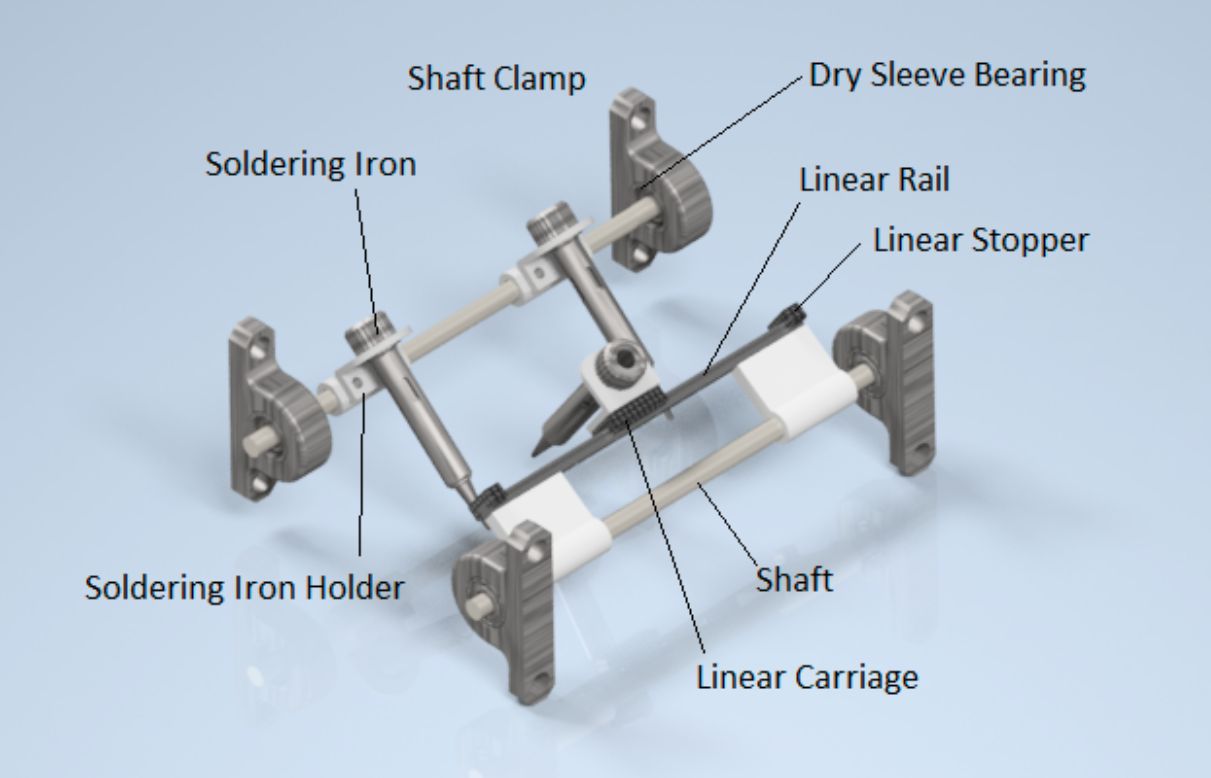

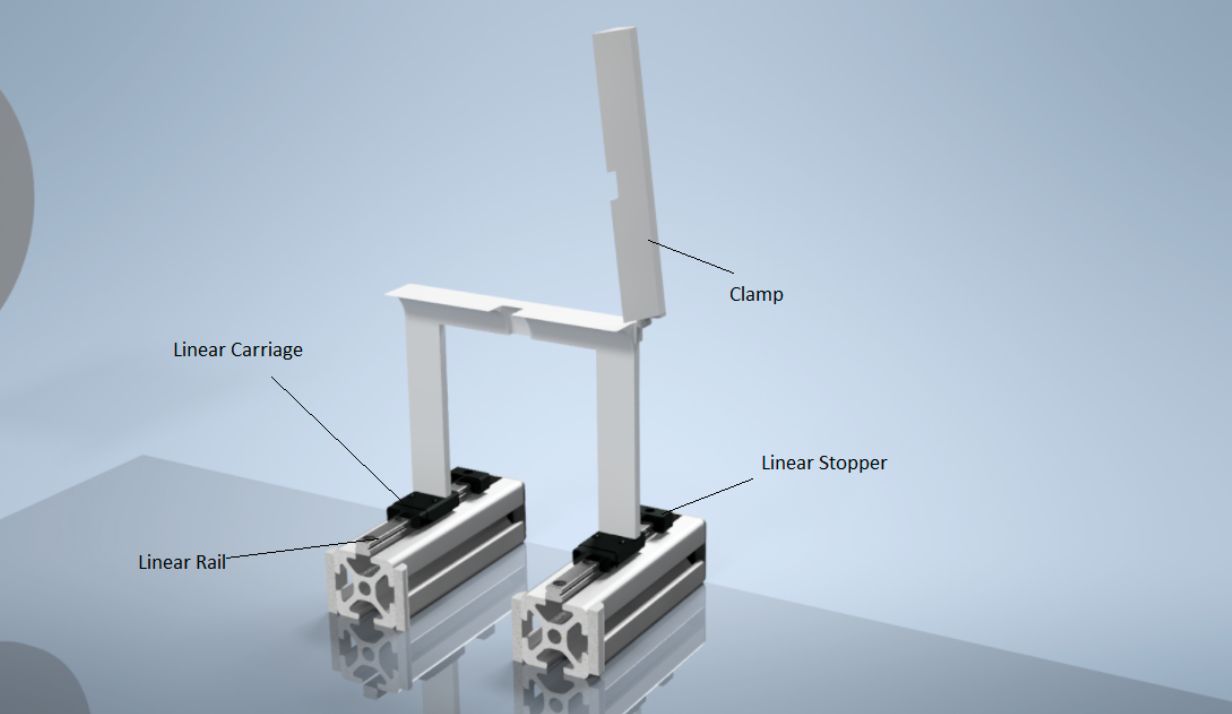

Various heating elements: soldering iron, hot knife, clamp heating element, long blade seal, number of heating elements

Different angles of heating element

Different pressures

Spec B

Will guard rail prevent hands from contacting heating elements

Spec C

Visually examine seal quality

Testing remaining flap strength, possibly with Instron machine

Check consistency of seal quality between each filter

Spec D

Count touch points during operation

Spec E

Black light testing for contaminants

Spec F

Visual inspection for divots

Spec G

Place cores into machine to see if they fit properly

Slide the second heating element over to ensure it accommodates cores.

Slide longitudinal heating element across to ensure there is enough room to accommodate cores.

Spec H

Time the filter wrapping process

How many can we do in an [Redacted]

Spec I

Can the process be done with one technician or will other help be needed

Spec K

Place each tape roll on the dowel to see if they both fit and able to roll out tape

Engineer’s Assessment

Potential Problems and Complications with current design ideas:

- Heating devices need to not interfere with the wrapping process.

- Rotating core at speeds/pressure could create tearing/stretching

- Holding wrap in place for first axial seal

- Guaranteeing that wrapping feed is tight enough to avoid slack but loose enough to prevent stretching

- Creating enough tension in the wrap to avoid wrinkles or excess, but not enough to stretch or tear material.

- Cutting material in such a way as to no stretch or pull, must cut straight across.

- Keeping the area with core open enough to allow safe installation and removal of cores.

- Applying adequate pressure from thermal heating devices for appropriate seals