Self-Sealing Nitinol Lid

Boise State professor, Dr. Deng, runs a lab which researches smart materials, like Nitinol. This material is a shape memory alloy, capable of being deformed from its trained shape. The material returns to its trained shape when heat is applied. The purpose of this project is to create a Nitinol demonstration for Dr. Deng to showcase, in hopes of peaking interests and gaining more funding for his research. The product is a coffee cup lid capable of self-sealing the drinking spout and expanding the silicon seal to press fit the lid into the mug, while the contents of the mug are hot. The goal of the product is to allow the user access to the contents of the mug, only after they are a safe temperature.

The Team

Members

- Johnny Howard

- Carolyn Murrey

- Caleb Picklesimer

- Dylan Rolleigh

Project Sponsor

Dr. Zhangxian Deng,

Smart Materials and Systems Laboratory

Capstone Design Coordinator

Self-Sealing Nitinol Lid

Self-Sealing Nitinol Lid

Problem Statement

Dr. Dan Deng, a research faculty member at Boise State University, requires a way to display the unique abilities of the smart materials he works with; Nitinol. The client requires a design which will quickly demonstrate the capabilities of this smart materials to gain interest and funding relating to his research. A successful design will be portable and display the materials’ abilities in a striking and unique way.

Benchmarking

EngineerGuy video

Pros:

-

Uses Nitinol which is cheap and easily accessible

-

Demos a working engine made from the material (intriguing and eye catching)

-

Minimal materials needed to set up the demonstration

Cons:

-

May require extensive work to make engine run

-

Not an original Demo idea

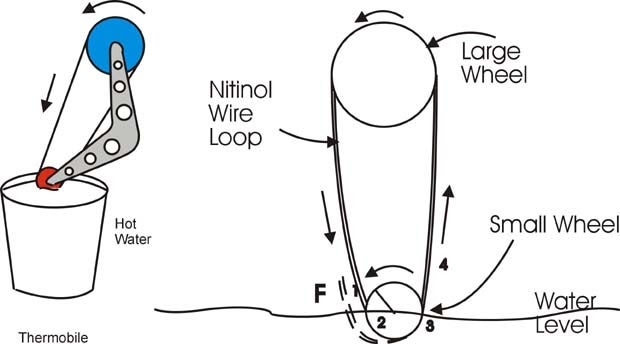

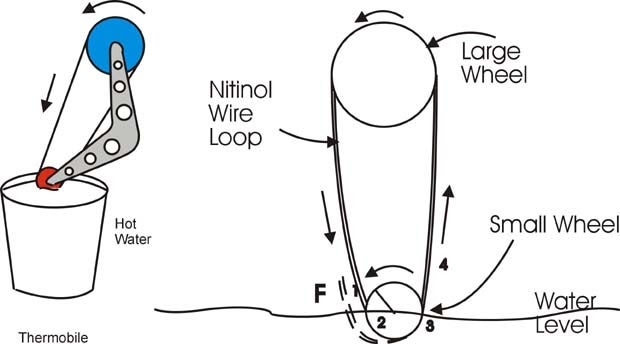

Summary: The EngineerGuy video does a great job explaining both the properties of Nitinol and how it powers a motor with temperature difference. This is a great demo where the audience immediately asks, “How is that motor being powered?” There are many other examples of Nitinol motors. See – Ice Water and Warm Water; 5 MW Nitinol Motor by McDonnell Douglas

Metallic Muscles with Shape Memory

Nitinol – Metallic Muscles with Shape Memory

Pros:

- Can personalize this demo – create Boise “B”

- Uses Nitinol – cheap and accessible

- Easy setup – only requires material and hot water

- Portable

Cons:

- Too popular of a demo

- Not striking to some people who are already familiar with shape memory materials

- First level demo of nitinol properties – does not integrate this behavior into a design

Summary: This is the most popular demonstration of smart materials on the web. This is the easiest thing we could do and does not require much engineering even if we try to customize the experiment to market Dr. Deng or BSU. Although, this could be a good starting place to brainstorm a device that takes advantage of this behavior of Nitinol.

Self-Bending Paperclip

Nitinol Memory Change Self Bending Paperclip Illusion Mentalism Magic Trick Toy

Pros:

- Portable and airplane safe

- Inexpensive: $2.19

- Quickly demonstrates Nitinol’s abilities

- Can be packaged as a magic trick

Cons:

- Very Basic

- Too Fundamental

- Very common

Summary: While this product shows the memory shape ability, it is not attention-grabbing and does not showcase the abilities of Nitinol in a way that would draw interest to the client’s research.

Background and Problem Analysis

EngineerGuy video

Pros:

-

Uses Nitinol which is cheap and easily accessible

-

Demos a working engine made from the material (intriguing and eye catching)

-

Minimal materials needed to set up the demonstration

Cons:

-

May require extensive work to make engine run

-

Not an original Demo idea

Summary: The EngineerGuy video does a great job explaining both the properties of Nitinol and how it powers a motor with temperature difference. This is a great demo where the audience immediately asks, “How is that motor being powered?” There are many other examples of Nitinol motors. See – Ice Water and Warm Water; 5 MW Nitinol Motor by McDonnell Douglas

Metallic Muscles with Shape Memory

Nitinol – Metallic Muscles with Shape Memory

Pros:

- Can personalize this demo – create Boise “B”

- Uses Nitinol – cheap and accessible

- Easy setup – only requires material and hot water

- Portable

Cons:

- Too popular of a demo

- Not striking to some people who are already familiar with shape memory materials

- First level demo of nitinol properties – does not integrate this behavior into a design

Summary: This is the most popular demonstration of smart materials on the web. This is the easiest thing we could do and does not require much engineering even if we try to customize the experiment to market Dr. Deng or BSU. Although, this could be a good starting place to brainstorm a device that takes advantage of this behavior of Nitinol.

Self-Bending Paperclip

Nitinol Memory Change Self Bending Paperclip Illusion Mentalism Magic Trick Toy

Pros:

- Portable and airplane safe

- Inexpensive: $2.19

- Quickly demonstrates Nitinol’s abilities

- Can be packaged as a magic trick

Cons:

- Very Basic

- Too Fundamental

- Very common

Summary: While this product shows the memory shape ability, it is not attention-grabbing and does not showcase the abilities of Nitinol in a way that would draw interest to the client’s research.

Stakeholder Analysis

Operator

-

Safety – operator is directly handling the product, assembling it, transporting it and demonstrating it. So, the product must be safe to handle (no exposed/ overly sharp edges, no parts that need excessive heat, etc.)

-

Ease of Use – the product needs to be easy to assemble, transport and demonstrate

-

Ease of Storage – product design should be compact enough for easy storage during transportation

-

Efficient Demonstration – the product should allow for a quick and almost effortless demonstration

Client

-

Effective Demonstration – since the point of the product is to draw attention to Dr. Deng’s research, he is affected by how effective the demonstration is at promoting the capabilities of the smart materials

-

Longevity – the product should be usable by the client for more than a single demonstration, therefore he is affected by the length of the product’s life

Manufacturer

Simplicity – manufacturing time is directly effected by the simplicity of the design and its components

Needs

| Need # | Description of Need | Justification | Required |

|---|---|---|---|

| 1 | Safe for operator during all stages of operation | Background and Problem Analysis, Table 1, Section 1, 2. | √ yes |

| 2 | Nitinol and/or PZT material used in design | Background and Problem Analyses Table 1, Section 3. | √ yes |

| 3 | Unique design that attracts onlookers attention | Background and Problem Analyses Table 1, Section 4. | √ yes |

| 4 | Quick and easy to assemble | Background and Problem Analysis, Table 1, Section 6. | √ yes |

| 5 | Simple and easy to use | Background and Problem Analysis, Table 1, Section 7. | √ yes |

| 6 | Portable enough for a single person to transport | Background and Problem Analysis, Table 1, Section 2. | √ yes |

| 7 | Cost minimized where possible | Background and Problem Analysis, Table 1, Section 9. | √ yes |

| 8 | Durable | Background and Problem Analysis, Table 1, Section 5. | √ yes |

| 9 | TSA approved for airline travel | Background and Problem Analysis, Table 1, Section 8. | no |

Specifications

| Spec Item. | Related Need # | Specification | Justification and Reference | Required |

|---|---|---|---|---|

| A. | 1 | Device will not harm or endanger any operator or spectator | Background and Problem Analysis:

Table 1, Section 1 |

√ yes |

| B. | 1, 7 | Weighs less than 50 pounds

(OSHA recommendation and convenience) |

Standards and Regulations,

Section 1 |

√ yes |

| C. | 2, 3, 4 | Nitinol and/or PZT is a featured material in the device | Background and Problem Analysis:

Table 1, Section 1 |

√ yes |

| D. | 5, 6 | Assembly and operation can be performed by one person | Background and Problem Analysis

Table 1, Section 2 |

√ yes |

| E. | 9 | Product can be used for at least 8 hours | Benchmarking

Table 1, Sections 1, 2, 6 |

√ yes |

| F. | 8 | Design and testing will cost $500 or less | Background and Benchmarking

Table 1, Section 5 |

√ yes |

| G. | 10 | Conforms to TSA guidelines for checked baggage | Background and Problem Analysis

Table 1, Section 2 |

no |

| H. | 7 | Disassembled dimensions are within a volume of 9x14x22 inches.

(Adheres to most airline carry-on luggage specs) |

Background and Benchmarking

Table 1, Section 2 |

no |

Form and Function

Operator

-

Safety – operator is directly handling the product, assembling it, transporting it and demonstrating it. So, the product must be safe to handle (no exposed/ overly sharp edges, no parts that need excessive heat, etc.)

-

Ease of Use – the product needs to be easy to assemble, transport and demonstrate

-

Ease of Storage – product design should be compact enough for easy storage during transportation

-

Efficient Demonstration – the product should allow for a quick and almost effortless demonstration

Client

-

Effective Demonstration – since the point of the product is to draw attention to Dr. Deng’s research, he is affected by how effective the demonstration is at promoting the capabilities of the smart materials

-

Longevity – the product should be usable by the client for more than a single demonstration, therefore he is affected by the length of the product’s life

Manufacturer

Simplicity – manufacturing time is directly effected by the simplicity of the design and its components

Analysis of Performance

Initial Nitinol Testing

The team was unfamiliar with the characteristics of Nitinol prior to beginning the project, so initial testing was conducted to learn more information on Nitinol and its shape memory behaviors. The following is an overview of the testing procedure and a summary of the results. It should be noted that while this testing was an attempt to quantify the force Nitinol is capable of producing, the quantified results are unreliable. Instead, the team used the trends of the results, paired with prototype testing, to make design decisions

The following procedure is adapted from a high school material science activity guide.

Testing Procedure:

- We are going to calculate the force of the memory wire. Place a piece of Nitinol on a tall flat surface, like a table, with 9 inches of wire hanging over the edge of the surface.

- Take your piece of Nitinol wire and a mass set. Then you will bend your Nitinol wire to a right angle with the edge of the table.

- You will hold one end of the Nitinol wire against the table, possibly with tape. Make sure you have a good grip because it may move. The other end of the wire should be bent into a hook shape.

- You want a small hook at the end of the wire, as achieved when you take a pencil and wrap the last centimeter of the wire over the pencil.

- Starting with the smallest mass (8.5 g), you will then hook your mass to the wire (you may use an additional centimeter of tape to tape the mass and the wire together). The mass should be hanging at the end of the wire.

- Take your hairdryer and set it to high heat. Direct the hairdryer so the heat hits the part of the wire bent at the edge of the table. Hold the hairdryer in a way so it is directed down (be sure to not be directing the heat at yourself or others). Heat the wire for no more than 25 seconds.

- Observe whether the wire is able to lift the mass and record data in the data table.

This testing procedure was followed using 1 mm wire with a transition temperature of 15C, 45C, and 80C. The results showed a trend that the higher transition temperatures were capable of lifting higher masses. However, Dr. Deng could not confirm that this trend would appear in our later experimentation.

The testing procedure was also used to examine 2 mm wire with a transition temperature of 60C. This wire proved to lift higher masses and these results were confirmed by Dr. Deng.

Testing of Performance

Initial Nitinol Testing

The team was unfamiliar with the characteristics of Nitinol prior to beginning the project, so initial testing was conducted to learn more information on Nitinol and its shape memory behaviors. The following is an overview of the testing procedure and a summary of the results. It should be noted that while this testing was an attempt to quantify the force Nitinol is capable of producing, the quantified results are unreliable. Instead, the team used the trends of the results, paired with prototype testing, to make design decisions

The following procedure is adapted from a high school material science activity guide.

Testing Procedure:

- We are going to calculate the force of the memory wire. Place a piece of Nitinol on a tall flat surface, like a table, with 9 inches of wire hanging over the edge of the surface.

- Take your piece of Nitinol wire and a mass set. Then you will bend your Nitinol wire to a right angle with the edge of the table.

- You will hold one end of the Nitinol wire against the table, possibly with tape. Make sure you have a good grip because it may move. The other end of the wire should be bent into a hook shape.

- You want a small hook at the end of the wire, as achieved when you take a pencil and wrap the last centimeter of the wire over the pencil.

- Starting with the smallest mass (8.5 g), you will then hook your mass to the wire (you may use an additional centimeter of tape to tape the mass and the wire together). The mass should be hanging at the end of the wire.

- Take your hairdryer and set it to high heat. Direct the hairdryer so the heat hits the part of the wire bent at the edge of the table. Hold the hairdryer in a way so it is directed down (be sure to not be directing the heat at yourself or others). Heat the wire for no more than 25 seconds.

- Observe whether the wire is able to lift the mass and record data in the data table.

This testing procedure was followed using 1 mm wire with a transition temperature of 15C, 45C, and 80C. The results showed a trend that the higher transition temperatures were capable of lifting higher masses. However, Dr. Deng could not confirm that this trend would appear in our later experimentation.

The testing procedure was also used to examine 2 mm wire with a transition temperature of 60C. This wire proved to lift higher masses and these results were confirmed by Dr. Deng.

References

Works Cited

- “Occupational Safety and Health Administration,” U. S. Department of Labor, 2020, accessed Mar. 1st, https://www.osha.gov/SLTC/etools/electricalcontractors/materials/heavy.html

- “Nickel Titanium Alloy,” ScienceDirect Journals and Books, 2020, accessed Feb. 20th, https://www.sciencedirect.com/topics/materials-science/nickel-titanium-alloy

- “International Carry On Size,” World Traveler, 2019, accessed Mar. 1st, https://www.worldtraveler.com/travel-101/airline-restrictions/international-carry-on-size