Climbing Carabiner Stress Field Map

Project Details

3D Printing Mentality seeks to promote additive manufacturing technologies through outreach and project sponsorship. The goal of this project was to utilize stress optimized inner lattice generation techniques coupled with robust simulations to design a novel climbing carabiner capable of meeting all standard ASTM requirements while reducing weight. In addition to optimization of the product, the team sought to quantify the “techno-economic fit” of low quantity production of the device compared to low quantity prototyping afforded by other methods. This goal was achieved through testing analog components against simulated predictions before going through an iterative design process to create a simulation-informed final design. The final design was printed utilizing Bound Powder Extrusion with the Metal X printers from Markforged, which allowed a wide range of geometries and relatively low lead times. The material used for the final product is 17-4 PH stainless steel, known for its corrosion resistance and high levels of strength and hardness, especially when heat treated. The final design was then verified through tensile tests designed according to ASTM standards for climbing carabiners and completed in the BSU materials testing lab.

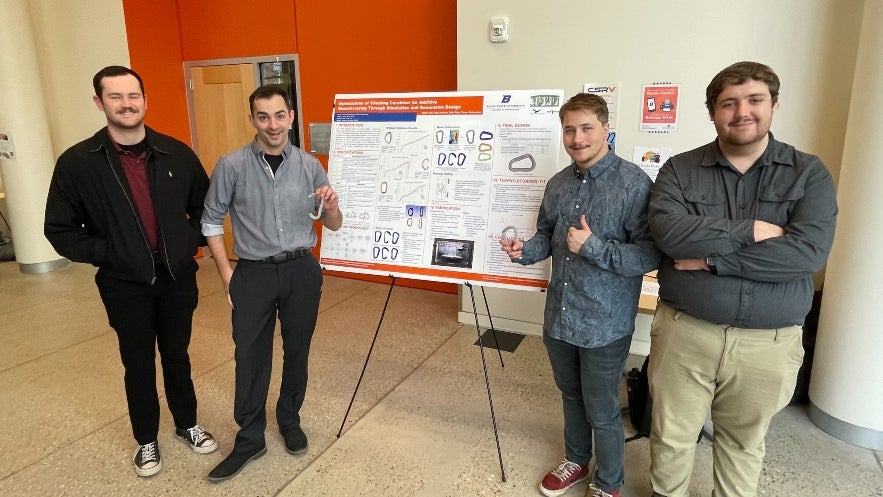

Team Members

Blake Hall

Gale Hansen

Seth Reis

Trevor Robertson

Department

Mechanical and Biomedical Engineering

Mentor

Aaron Smith, Ph.D.

Harold Ackler, Ph.D.

Matthew Shomper

Sponsor

3D Printing Mentality, Steven Szymeczek and Zack Richter