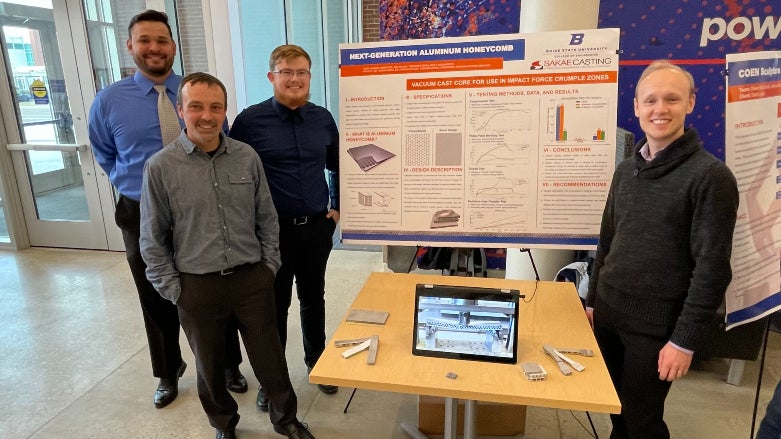

Honeycombed Aluminum Samples

Project Details

Sakae Casting tasked this team with conducting product ideation to find a use for their novel unique aluminum precision vacuum casting technologies. The team worked with Sakae to develop a cellular lattice which replaces the traditional hexagonal columns as the core of aluminum honeycomb. The “sandwich” is fabricated with this aluminum core and can be surfaced with a variety of materials depending on the purpose. The primary application of the aluminum lattice core is to be used as a crumple zone within a larger system and is designed to absorb the impulse load from impact forces. By performing multiple destructive and non-destructive tests on Sakae’s, and competitor benchmarks’ samples, Team Prosperity’s test data supports the idea that the lattice core casted by Sakae is superior to that of traditional aluminum honeycomb.

Team Members

Joe Keller

Samuel Anderton

Riley Woodworth

Tim Sansoterra

Department

Mechanical and Biomedical Engineering

Mentor

Aaron Smith, Ph.D.

Harold Ackler, PhD

Lynn Catlin, PE

Steven Howe

Sponsor

Sakae Casting; Mika Fox and Iwasawa Satoshi