Think you can create the planet's most efficient ice rink?

(Good Luck).

You’ll never guess what critical choices you’ll be forced to make if your goal is to build the most efficient HVAC system for a facility with two Olympic sized ice rinks. Will the system use direct cooling? Or will you go with the indirect system? Also- what refrigerant is most optimal to use: Ammonia, CO2, or Freon? Do you use the waste heat from the system to heat other parts of the building? What sort of Cooling loads will have to be dealt with? Are you still keeping up? These decisions and more must be considered to ensure that yours can be the most efficient one on Planet Earth. I bet it’s more than you thought, isn’t it?

The Team

Members

- Jonathan Bowman

- Robert Herlt

- Adam King

- Andrew Knutson

- Matt Mahoney

Capstone Design Coordinator

Creating the most efficient ice rink

Ice skating facility HVAC and refrigeration design

Problem Statement

Mr. Lynn Catlin desires an HVAC system and an ice rink refrigeration system design for a duel indoor ice rink with area of 73,000 (sq. ft). The design will include heating, ventilation, and air conditioning for the entire complex to include cooling at least one ice rink. Energy efficiency for the building is the main focus of the design. The complex will have a 25 year life span and will need to be profitable to continue its operation.

Who:

This project is presented by a single individual, Lynn Catlin, who represents a larger endeavor.

What:

Design the most efficient HVAC system for an indoor Ice rink plus central area with locker rooms, bar, etc. This includes cooling the ice, and insulating the facility.

Why:

Success of this project will provide a 25 year business to the Treasure Valley location. A more efficient building leads to a higher profit margin, hence why thermal efficiency is the priority

Details that are indispensable:

- HVAC stands for heating, ventilation, and air conditioning.

- An ice rink absorbs a lot of heat, thus keeping the ice rink cold is a top priority. Keeping this in mind, the design needs to make this process extremely efficient.

- Building must be aligned to take into account the heating effect of the sun.

Attributes for a successful solution:

- Careful research into the weather and how it affects the buildings of Treasure Valley.

- Careful planning and researching ice rink designs

- Research and planning HVAC design.

- Determining whether to use Ammonia or CO2 as refrigerant.

- Look at insulating the facility

- Controlling the emissivity of the roof.

- 1 ice rink is official, but plan for two.

- Cooling the locker rooms, common areas and grille cannot be overlooked.

Standards and Regulations

Item 1: Meridian ID, Code of Ordinances (“Adopted Codes and Design Criteria,” n.d.)

This code sets forth all standards listed below, to be used as codes inside of this code. This code also amends standards listed below, and those amendments will be used in replacement of the standard.

Item 2: Maintenance – ASHRAE standard 180-2018

(ASHRAE) The American Society of Heating, Refrigerating and Air-Conditioning Engineers

This discusses standards for allowing easy maintenance and inspection of HVAC systems.

Item 3: HVAC efficiency – ASHRAE standard 90.1-2019

This discusses minimum energy efficiency requirements for constructing HVAC systems and includes energy saving measures to achieve energy levels above the minimum required.

Item 4: Ice Rink Construction – IMC 2018 sections 1108 – 1109

(IMC 2018) International Mechanical Code 2018

These sections discuss standards for building and ice rink construction.

Item 5: Duct sizes and material – ANSI/SMACNA 006-2006

(ANSI) American National Standards Institute

(SMACNA) Sheet Metal & Air Conditioning Contractors’ National Association

This discusses standards for HVAC duct construction.

Item 6: Environmental – IECC standards C403-407

(IECC) International Energy Conservation code

This discusses standards for energy efficiency of HVAC systems, so that they obey environmental laws and release as little emissions as possible.

Item 7: Comfort for human occupants – IECC standards C403-407

This discusses standards for maximizing the comfort of human occupants.

Benchmarking

Internal Heating Method to Reduce Cost

How to Significantly Reduce The Cost Of Ice Rink Heating

This method allows for the spectators to be comfortable while reducing the load on the ice rink to stay cold.

Pros:

- Aim Heaters to stands and away from ice

- Keeping a minimum number of heaters in facility

- Base board heating

Cons:

- Adding heat to the facility will cause the ice to melt more quickly

- Will increase cost of facility

- Essential for comfort of spectators

Ice Rink Floor System

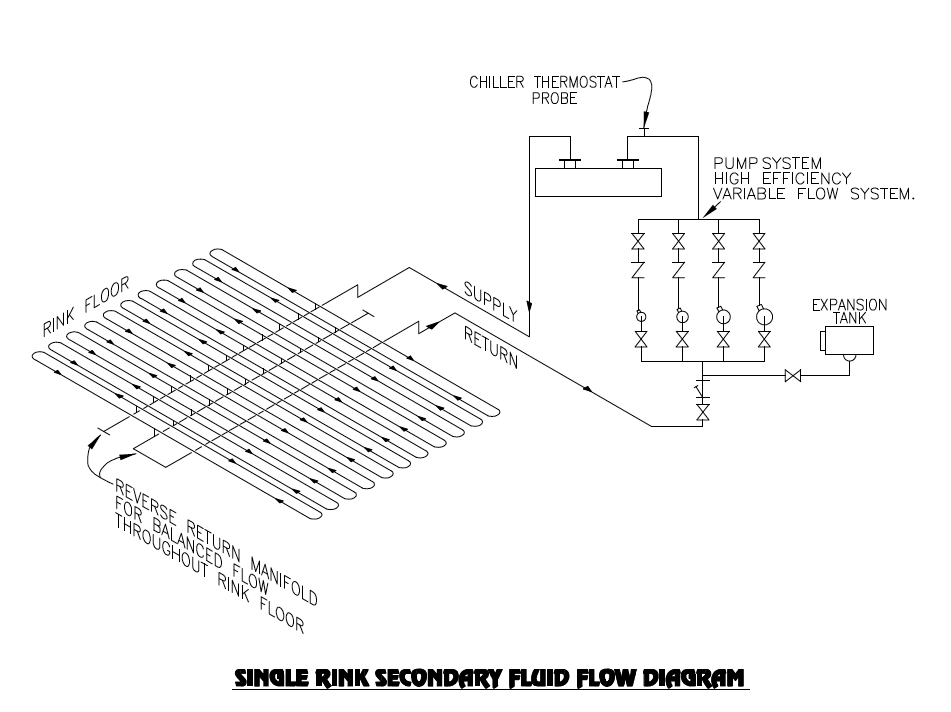

Recreational Ice Rink Chiller Systems

This method allows for even disruption of temperature and reduces damage to other parts of the system.

Pros:

- Keeps ice cold and conserves energy

- Heats ground below rink to reduce cracks

- Change in temperature can be more forgiving

Cons:

- This method uses a brine/water to keep cold

- Needs 5 miles of steel pipe under the rink

- Solution is custom

How Outdoor Rinks Stay Frozen

How are outdoor ice skating rinks kept frozen in warmer climates?

The method of using Glycol to maintain temperature is interesting and gives possibilities other than the standard practices.

Pros:

- Stay cold even in warm/hot conditions

- Uses Glycol as cooling agent

- Rink temperature is easy to manipulate

Cons:

- Outdoor rink

- Glycol may not be cost-efficient

- Rinks are not open all year round

Direct Refrigeration System

Refrigeration Systems keep NHL arenas on ice

This method allows for the rink to be cooled with a consistent system and the ability to save energy with heat reclaim. Overall the heat reclaim process will have a higher impact on our system.

Pros:

- More efficient that indirect

- Heat can be reclaimed for other purposes, such as heating other rooms

- Uses standard pipes and equipment

Cons:

- Higher rinks of leaked refrigerant

- Need more safety protocols

- Has to use refrigerant or ammonia

Background and Problem Analysis

Tasks that require further research to best design an HVAC system for an ice rink:

- Establish different methods of ice cooling:

- CO2 cooling.

- Glycol cooling.

- Calculate the areas and volumes of each part of the building.

- Load calculations in progress, estimated completion Nov 2020.

- Sub-divide the facility into ‘Zones’ in order to determine most and least efficient areas of the building.

- Do ‘Best Practices’ exist for this process?

Questions we need answered from the client:

- Confirmation of square footage requiring HVAC / Chilling.

- Common Area: ~23,000 sq ft / Phase 1 Construction.

- Ice Rink 1: ~25,000 sq ft / Phase 1 Construction.

- Ice Rink 2 (future build): ~25,000 sq ft / Phase 2 Construction.

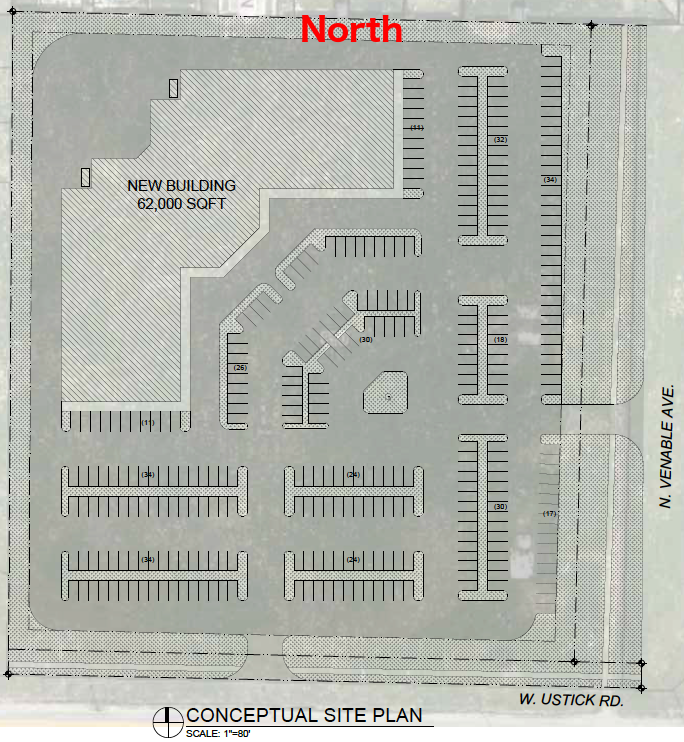

- What location and direction will the building face?

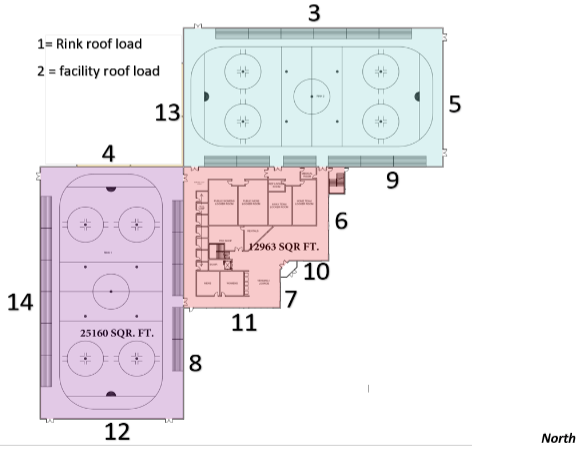

- see Figure 1 below.

Estimated heat calculations

- Refer to figure 1 above for corresponding wall number.

- Note: There is a quantity of 2 for wall # 1

| Wall # | Heat load for wall (btu/h) | Wall # | Heat load for wall (btu/h) |

|---|---|---|---|

| 1 | 322,148 | 8 | 9,608 |

| 2 | 110,433 | 9 | 14,572 |

| 3 | 23,411 | 10 | 4,543 |

| 4 | 17,743 | 11 | 10,021 |

| 5 | 17,743 | 12 | 26,909 |

| 6 | 5,717 | 13 | 33,423 |

| 7 | 2,592 | 14 | 44,101 |

| SUM | 965,000 (btu/h) |

Appendix A: Contains load calculations spreadsheet.

Criteria that are often missed when defining efficiency for a facility

- Minimum of 5 months of running the facility.

- Heat loads of concession stands and other related vendors.

- Heat loads of skaters, visitors, and employees.

- Weekly ice resurfacings per rink, typically minimum of 4 times.

- Determining max operation time of 24/7.

- Heat loads generated by scheduled deliveries.

- Max ice resurfacing 100 times.

- Chilling ice is approximately 40% of the energy facility budget.

- Annual costs range from 600,000 kWh to 2000 MWh yearly (“Energy efficiency in the ice Rink,” 2000).

Items to consider that will impact energy cost:

- Concrete surface below ice.

- Determine which cooling agent will be most efficient between CO2 or Glycol.

- There is an Ice Rink standard for surfaces.

Design Considerations that may improve HVAC efficiency

- Keeping a minimum number of heaters in the facility.

- Adding heat to the facility will cause the ice to melt more quickly.

- Position heating equipment away from the ice rink.

- Baseboard heating.

- Comfort and experience of spectators.

- Environment should be ~55 degrees F.

- Determine energy efficient material for walls.

- Windows will be in the front of the building, but no windows facing the outside will be part of the ice rink.

- There will be windows separating the heated eating area from the ice rink.

- Emissivity and shape of the roof will be provided by the customer.

- Purposeful system designs that allow efficient and effective maintenance.

- Optimize load calculations based on ‘Zones’ of the facility.

- This needs to include areas of food preparation, concessions, locker rooms, and 2nd floor office spaces.

- Include loads for future construction of additional ice rink (Phase 2 Construction).

Stakeholder Analysis

Maintenance Team/Operator

- Safety

- Ease of repair

- Maintenance schedule

Ice Rink Zone

- Keep the ice cold

- Keep spectators comfortable

Other Zones

- Keep locker room at comfortable temperature

- Keep concessions/employee area at appropriate temperature

Construction Team

- Safety

- Ease of construction

- Ease of obtaining parts/equipment

- Cost

General Staff

- Comfortable work environment

The Environment

- Chemical safety and disposal

Investors

- Building cost

- Maintenance and power cost

- Longevity of design

Needs

| Need # | Description of Need | Justification | Required (Y/N) |

|---|---|---|---|

| 1 | HVAC system must not release any dangerous byproducts that could harm customers or employees. | Safety is always a priority. | Y |

| 2 | HVAC system must be safe for employees to operate and maintain. | Safety is always a priority. | Y |

| 3 | HVAC system must be able to heat and cool ice rink and indoor areas all year round at max capacity. | Requirement for ice rink to continue generating profit | Y |

| 4 | Ice rink design and building must have a lifetime of at least 25 years. | Client requirement to generate profit and satisfy investor needs. | Y |

| 5 | The most energy efficient refrigerant must be identified for Meridian climate and used. | Client requirement to generate profit and satisfy investor needs. | Y |

| 6 | Costs of the facility must meet the available budget. | Client requirement. | Y |

| 7 | Vender and customer locations need to maintain comfortable temperature. | A comfortable environment is needed to maintain long term operation | Y |

| 8 | Roof and walls need to be made from materials with a low emissivity. | Client requirement to generate profit and satisfy investor needs. | Y |

| 9 | HVAC systems need to be easily accessible for future maintenance or upgrades. | Operators must be able to quickly and easily maintain the system. | Y |

| 10 | HVAC system must use standard sized ducts and other material. | Parts and cost for material will be more accessible. | Y |

| 11 | External buildings and areas must have energy loads that don’t impact the temperature of the ice rink system. | Reduction of external impact of the ice rink system reduces cost. | Y |

| 12 | Ice rink must be the most energy efficient facilities in the state. | Enables maximum profit. | N |

| 13 | Ice rink must be the most energy efficient facilities in the country. | Enables maximum profit. | N |

| 14 | Ice rink must be the most energy efficient facilities in the world. | Enables maximum profit. | N |

Specifications

| Spec. Item | Related Need # | Specification | Justification and Reference | Required (Y/N) |

|---|---|---|---|---|

| A | 1,2,9 | Conform to ANSI (American National Standards Institute) / ASHRAE (American Society of Heating, Refrigerating And Air-Conditioning) safety and maintenance standards. | Standards and regulations items 1 & 2 | Y |

| B | 3 | HVAC systems must provide adequate temperature control throughout the building year round at max capacity. | Client Requirement | Y |

| C | 4 | Ice Rink Refrigeration systems must adhere to IMC (International Mechanical Code) for the building’s expected lifetime of 25 years. | Standards and regulations items 1 & 4 | Y |

| D | 5,12,13,14 | HVAC (Heating, Ventilation, and Air-Conditioning) system must be energy efficient (consume less than 2,000,000KWh per year) to ensure profit. | Standards and regulations items 1 & 3 | Y |

| E | 6 | Costs of the facility must meet the available budget. | Client Requirement | Y |

| F | 7 | Conform to ASHRAE comfort standards | Standards and regulations items 1 & 7 | Y |

| G | 7 | Design a cooling load for the common area of the ice rink. (23,100 sq ft) | Client requirement | Y |

| H | 7 | Design a cooling load for 2 Ice Rinks (each 25,160 sq ft) | Client requirement | Y |

| I | 8,11 | Buildings must conform to IECC (international energy conservation code) standards (2015 Standard by Idaho Law) for insulation and emissivity. | Standards and regulations items 1 & 6 | Y |

| J | 10 | Duct sizes and duct materials must comply with ANSI / SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) standards. | Standards and regulations items 1 & 5 | Y |

Form and Function

HVAC System

An HVAC system is essential to maintaining a comfortable temperature for customers and employees. Areas other than the ice rinks can be held at a warmer temperature, while the ice rink must be held below 32F to prevent the ice from melting.

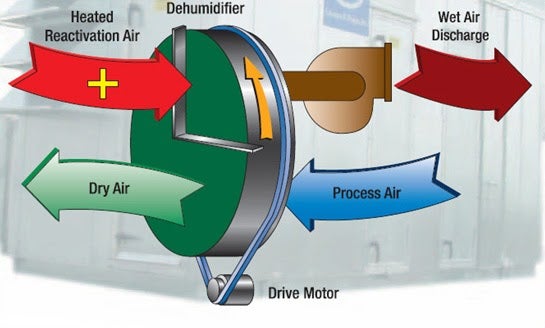

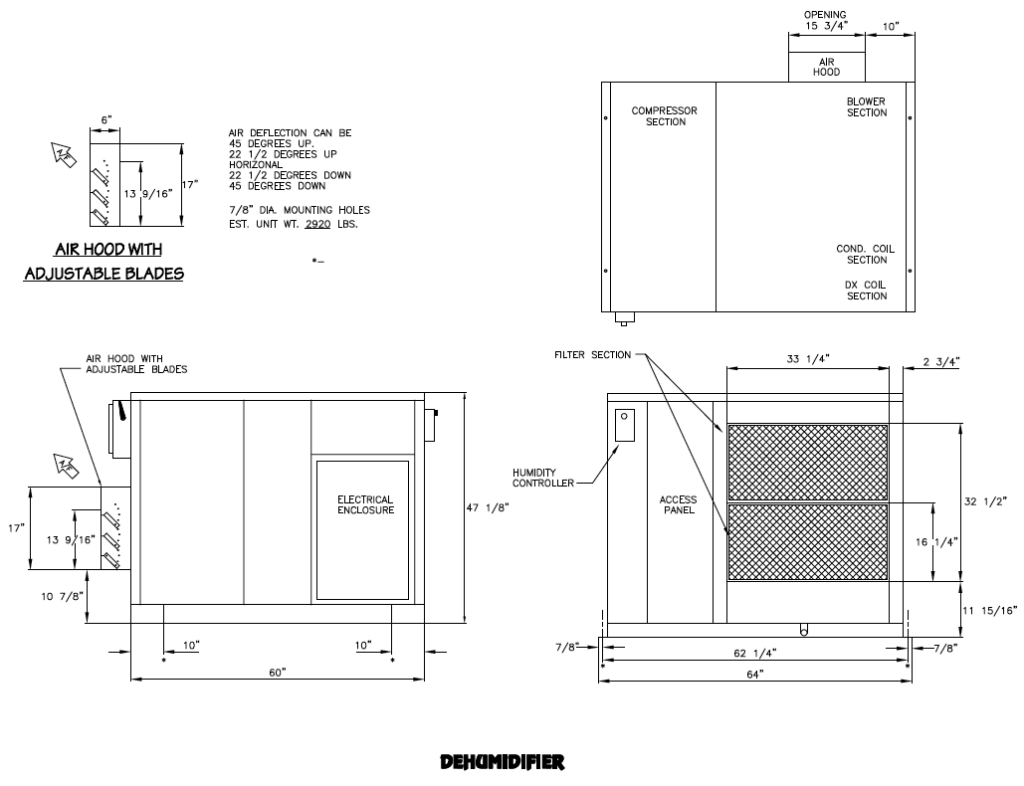

Dehumidifier

A dehumidifier is important for eliminating moisture, mold, mildew, and fog. Ice rinks are especially prone to humidity because of the large quantity of water involved in creating and resurfacing an ice rink. Humidity causes ice to become soft, which could be a danger for ice skaters. Resurfacing the ice would also become more difficult, generating unnecessary expenses. Furthermore, humidity causes mold and mildew to form, which is toxic to customers and employees inside the structure. To prevent these issues, a dehumidifier utilizing a process called desiccant dehumidification is employed, which uses an absorbent gel to remove moisture from the air. Benefits of the desiccant dehumidification process include easy maintenance, reliable construction, and high efficiency, which is especially important for this ice rink which prioritizes high efficiency to generate sufficient profit (“Desiccant Dehumidification for the Community Ice Arena,” 2013).

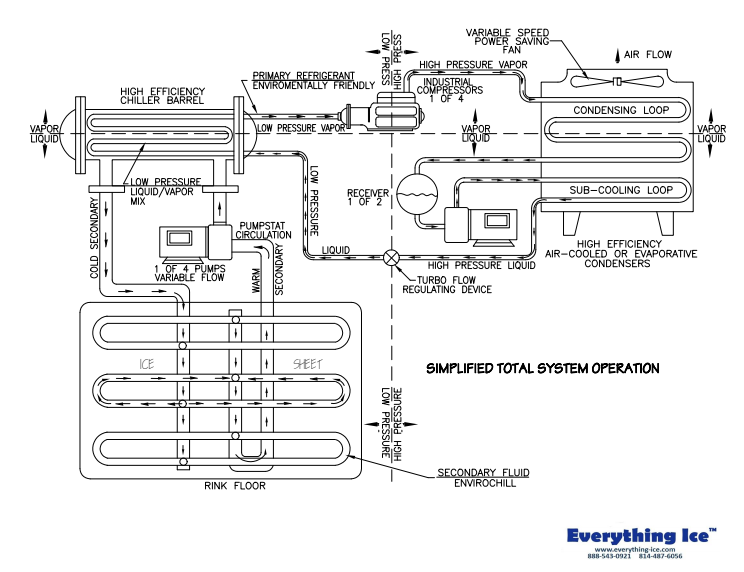

Chiller

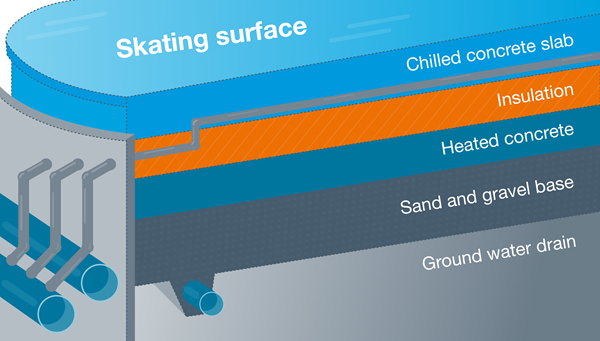

The purpose of a chiller is to keep the ice in the rink frozen. Underneath the ice is a set of pipes with brine water running through them. The brine water is cooled below freezing with a refrigerant (often ammonia). This method is called an indirect refrigeration system. To prevent the foundation from freezing and weakening, heated concrete is placed underneath a layer of insulation (“Ice Rinks: Refrigeration On A Big Scale,” n.d.)

DESIGN SOLUTION

HVAC System Overview

HVAC Location

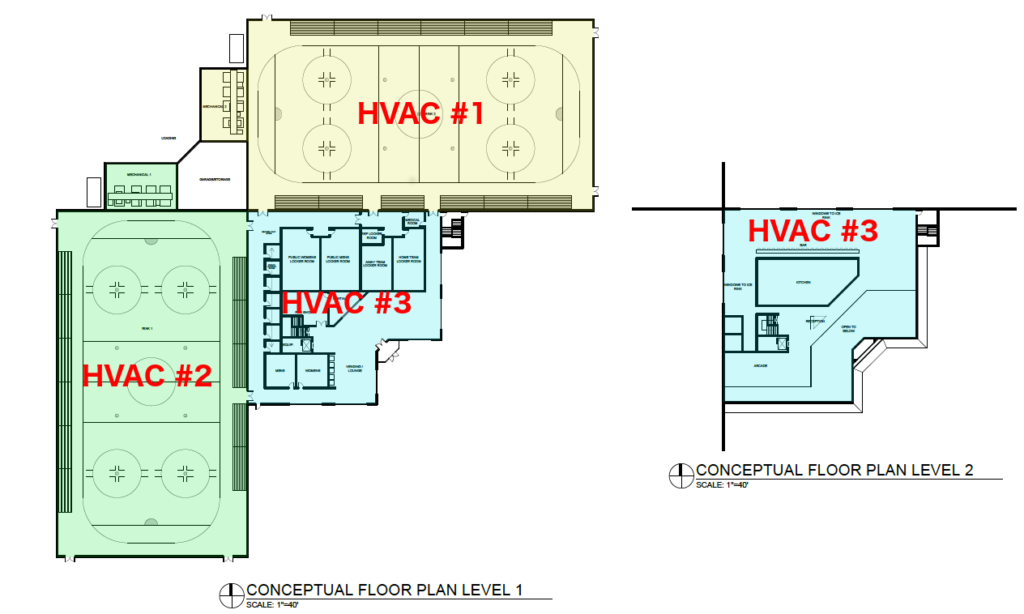

The ice rink will be using 3 HVAC systems, one for each ice rink and another used for the rest of building, including the lobby, bar, locker room, and other common areas as shown below. HVAC systems are most efficient when high in elevation, and so they will be mounted to the roof.

Dehumidifier

Chiller

Building Orientation

Energy efficiency is essential to generating profit necessary for maintaining operation. The building will be oriented to minimize thermal radiation from the rising and setting sun. No windows will be located on the west and east sides of the building in order to reduce thermal radiation.

Analysis of Performance

Analytical analysis of this design will be subjected to software simulation. This software will provide effective feedback on both the load and design of the HVAC system. The output of the simulation will impact future design decisions and validation. The input will focus on two key aspects of the design specificity within the ice chilling system. The analysis will validate each method for direct vs. indirect system and the heat transfer fluid.

Input:

- Load Calculations

- Room Locations (Zones)

- Building Orientation

- Weather Data

- System Types (i.e. split system, hybrid system, etc)

- Equipment information and performance

Output:

- Peak & Hourly Loads

- Airflow & Supply Air Temperature

- Equipment Loads

- Energy Consumption by Source

- Economic Comparisons or Alternatives

Testing of Performance

Testing performance for design will largely be implemented through software simulation. This will uncover and allow for effective design decisions to be made. Thus, the design will be prepared to present to an HVAC professional for final feedback. This feedback will consist of validation for heat load calculations and recommended equipment selection. The client is expected to provide or recommend a professional for validation. A professional has the experience to suggest cost beneficial changes that the simulation may not account for, such as minor layout changes to make maintenance more accessible. Finally, the feedback from the professional will be used to make final finite changes and confirm a final design.

Development Schedule

Development Summary

May

- Meeting to Discuss Concept Proposal

- Make necessary changes to Narrative

- Publish Narrative website

September

- Reevaluate load calculations and team briefing

- Update calculations if any facility plans have changed

- Prepare design to use both indirect and direct chilling system

- Prepare design to use CO2 and Ammonia chilling system

October

- Use design software to test preliminary HVAC system

- Use design software to test indirect and direct chilling system

- Use design software to test CO2 and Ammonia for best chilling results

- Evaluate results to modify or improve design efficiency

- Develop preliminary Bill of Materials

- Partner with client with cost analysis and decisions for final design

November

- Obtain approval for any major factors of the design

- Finalize any design changes due to performance results

- Draft plans and blueprints of HVAC Design

- Draft plans and blueprints of Chilling System Design

- Finalize Bill of Materials

December

- Present finalized design to the customer

Engineers’ Assessment

The design of the HVAC system must be able to provide heating and cooling in the ice rinks and common areas. The highest energy efficiency possible for a building of its size and layout. This is significant because a high energy usage would result in larger costs, cutting into the profit of the business. Since a high percentage of the facility’s energy consumption will be as the result of the ice rink system, the energy use of the system must be reduced to a level that provides sufficient profit to keep the building in business. Success of the design would result in an energy use that is lower than the average for a building of its purpose and square footage, while still being able to cool and heat the various parts of the building to their appropriate specifications.

If shortcomings are found during analysis and testing, it could prove useful to improve the HVAC systems used, along with their size and placement. This will be done by using software simulation to calculate the energy required to power the system needed to successfully cool and heat the building. For example, if one smaller sized HVAC system was used for each common area zone, would it be feasible and more energy efficient to use just one larger system for both floors? The type of HVAC system used could also be altered and implemented in a simulation of the expected energy use of the HVAC system, along with individual components like the pumps and fans. Finally, unless the building blueprint is set in stone, the thickness of insulation and building material used could be another variable to adapt. Software simulation will allow for multiple design decisions to be checked for best energy performance.

References

Adopted Codes and Design Criteria. (n.d.). Retrieved April 22, 2020

Desiccant Dehumidification for the Community Ice Arena. (2013, August 30). Retrieved April 22, 2020, from https://beckerarena.com/blog/desiccant-dehumidification-for-the-community-ice-arena/

Energy efficiency in the ice Rink. (2000, August 3). Retrieved April 22, 2020, from https://www.achrnews.com/articles/84022-energy-efficiency-in-the-ice-rink

Ice Rinks: Refrigeration On A Big Scale. (n.d.). Retrieved April 22, 2020, from https://www.howden.com/en-gb/articles/refrigeration/ice-rinks-refrigeration-on-a-big-scale

Principles of Heating, Ventilating and Air-Conditioning, 8th ed.