Welcome to our Fall event!

Wednesday, December 9

3:00 PM – 4:30 PM

Thank you for supporting our newest engineers! This year we offer a virtual showcase of student projects ranging from prosthetic limbs to ice skating rinks! Browse the projects below; you’ll have the chance to learn more on event day! Our teams are excited to share what they have accomplished and the lessons they learned along the way in live breakout sessions during the showcase event.

If you have any questions, please email Gus Engstrom (ME) or Amy Moll (ENGR+).

Capstone Design Teams

Opening Session

Opening Session

Join us for our opening session with greetings, welcomes, and how to navigate the Showcase!

3:00 – 3:25 PM

Mechanical and Biomedical Engineering – Session 1

Session 1: 3:30 – 3:55 PM

Choose a presentation to attend

Team ACRO

Teaching Robots to Walk

Our goal as team ACRO, is to design, develop, and test a high performance configurable acrobat style robot for controls algorithm development and demonstration. While using novel methods to ensure a unique and interesting design is achieved, we will meet professional manufacturing standards and the unique needs of the Boise State Robotics Lab. Understanding how to control this style of underactuated robot is one of the building blocks to more advanced walking robots.

Team CFM

Think You Can Create The Planet’s Most Efficient Ice Rink? (Good Luck).

You’ll never guess what critical choices you’ll be forced to make if your goal is to build the most efficient HVAC system for a facility with two Olympic sized ice rinks. Will the system use direct cooling? Or will you go with the indirect system? Also- what refrigerant is most optimal to use: Ammonia, CO2, or Freon? Do you use the waste heat from the system to heat other parts of the building? What sort of Cooling loads will have to be dealt with? Are you still keeping up? These decisions and more must be considered to ensure that yours can be the most efficient one on Planet Earth. I bet it’s more than you thought, isn’t it?

Team SMART

Self-Sealing Nitinol Lid

Boise State professor, Dr. Deng, runs a lab which researches smart materials, like Nitinol. This material is a shape memory alloy, capable of being deformed from its trained shape. The material returns to its trained shape when heat is applied. The purpose of this project is to create a Nitinol demonstration for Dr. Deng to showcase, in hopes of peaking interests and gaining more funding for his research. The product is a coffee cup lid capable of self-sealing the drinking spout and expanding the silicon seal to press fit the lid into the mug, while the contents of the mug are hot. The goal of the product is to allow the user access to the contents of the mug, only after they are a safe temperature.

Team SOKT

Not snug enough for you? This device keeps you tight all day long!

One of the most common issues that lower leg amputees have is finding the perfect fit for their prosthetic leg. Due to the amputee’s activity and diet, the volume of an amputee’s residual limb fluctuates throughout the day that distorts the fit of their prosthetic socket which leads to discomfort, pain, and sometimes even serious medical complications. A new prosthetic socket design is required which has the capabilities of sensing a change in the user’s volume around the residual limb and actively provides action to fix the situation. Using new software, our team derived a solution to allow for a socket to accommodate for this fluctuation.

Mechanical and Biomedical Engineering – Session 2

Session 2: 4:00 – 4:25 PM

Choose a presentation to attend

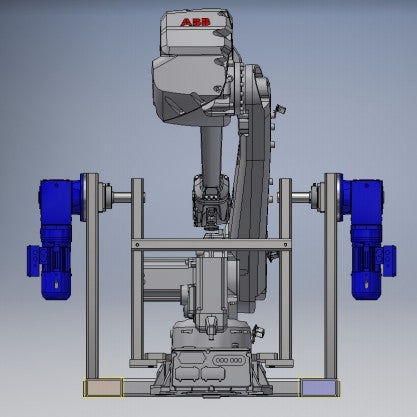

Team INVERT

Robot Inversion Installation Device

House of Design is an up and coming company which develops manufacturing lines utilizing robots for a wide range of innovative work. The company must often lift and mount robot arms weighing anywhere from 50-3000 lbs on shelves, walls, ceilings, and all angles between which can require the assistance of several employees. This can be extremely dangerous and time-consuming. The purpose of this project is to develop an installation device that would accommodate the lifting and rotation of a robot up to 180 degrees to mount at any angle the company could ever need. Therefore, a product is to be designed to help House of Design perform its daily tasks with increased safety and efficiency.

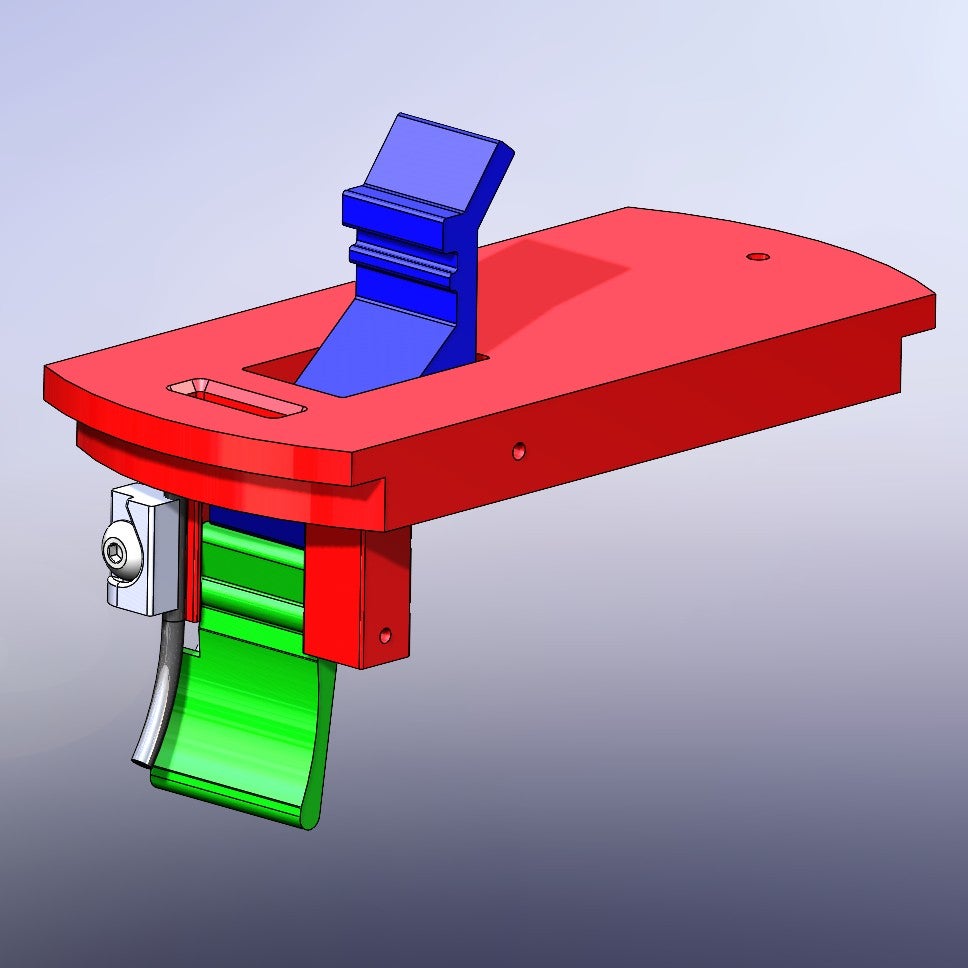

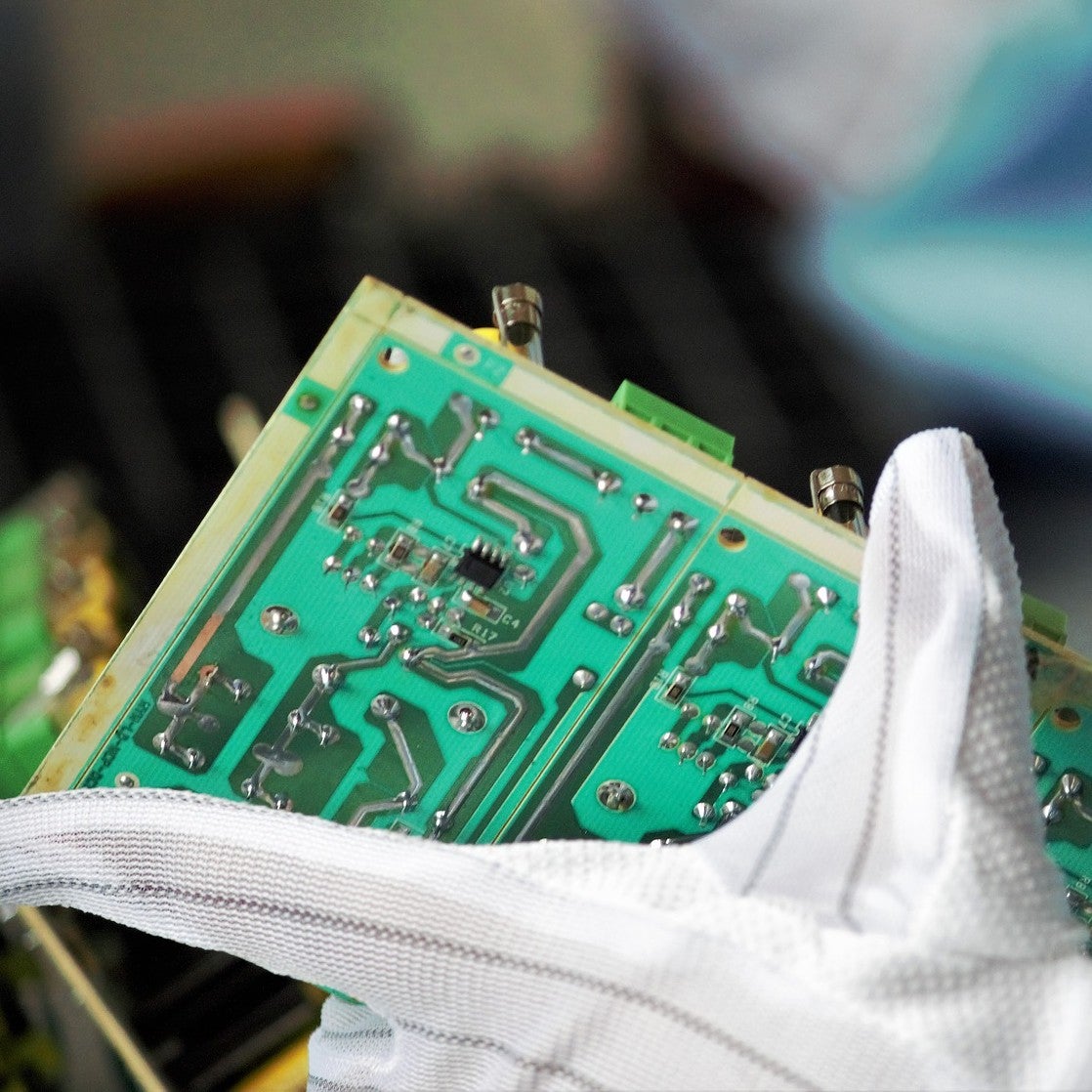

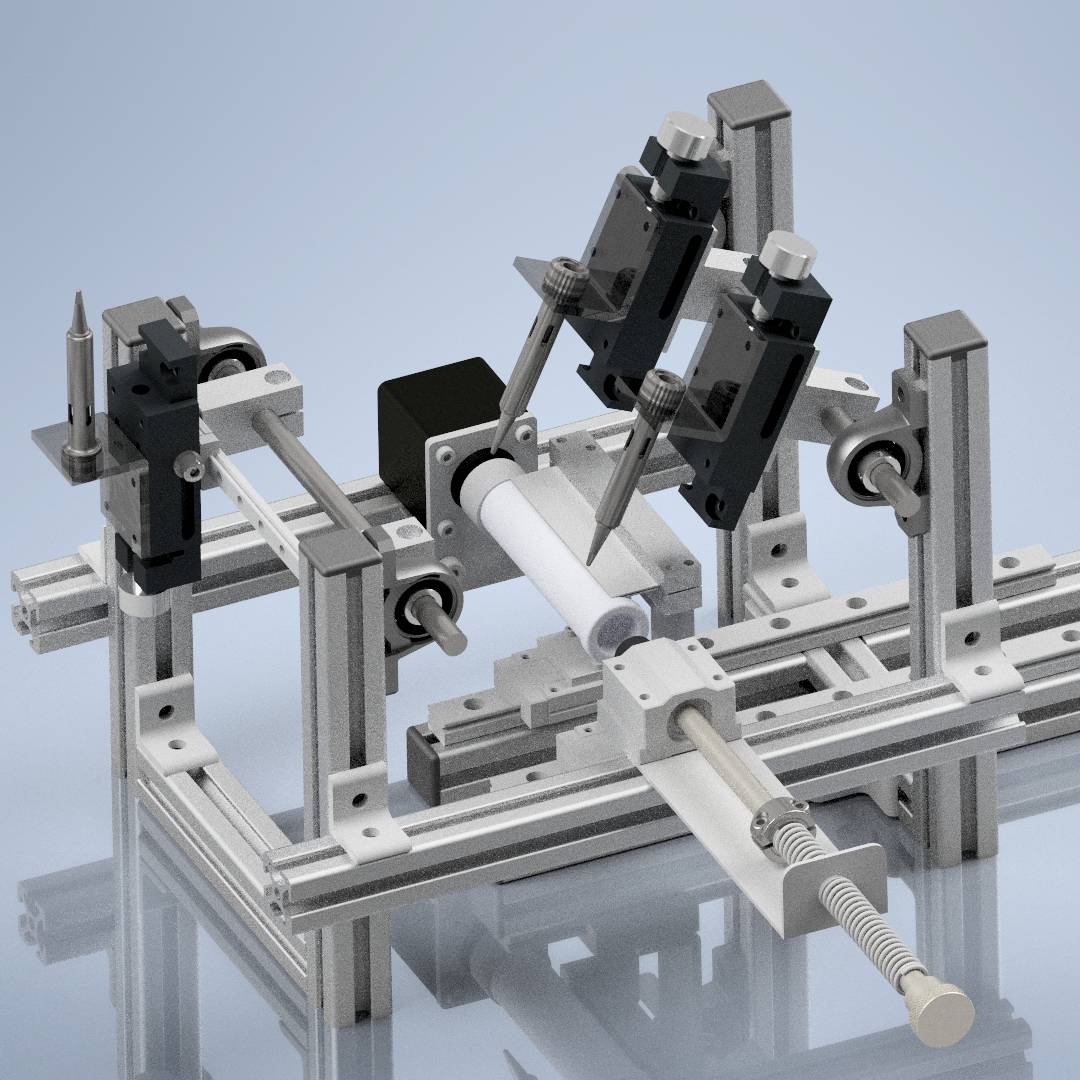

Team PCBFX

Universal PCB Fixture

Plexus, a contract electronics assembly manufacturer, was looking to create a universal printed circuit board (PCB) fixture. The fixture is being sought to augment the assembly process to prevent board and component damage during assembly, transportation, and accidental drops. The fixture adjusts to various board sizes and shapes, has access to both sides, handles large temperature fluctuations during manufacturing, and moves seamlessly with the PCB throughout the assembly process.

Team WRAPR

A novel method of reducing contamination on production of filter cores.

Porvair is working on innovating various aspects of their manufacturing processes in order to better accommodate the needs and requests of current and future clients. In regards to this, Porvair has offered a project to a talented team of future mechanical engineers at Boise State University in order to provide them with a viewpoint of a real world engineering project. The project explores analyzing a current manufacturing operation and developing a set of process improvements. Porvair requests a device to automate aspects of the process, thus reducing contamination and improving on the production rates of Porvair’s filtration products.

Engineering Plus – Session 1

Session 1: 3:30 – 3:55 PM

Choose a presentation to attend

Team APN

Universal Hands Free Door Opener

Here at Team APN we are working on new ways to do something incredibly simple, open a door. With the Coronavirus pandemic, our goal is to limit the spread of the virus by lowering risk of infection from high touch areas such as door handles, elevator buttons, crosswalk buttons, etc. Our team is exploring two separate solutions. The first is an attachment to the bottom of doors allowing the use of the foot to pull the door open. This design is detachable so as not to permanently damage the door. And the second solution is a handheld key chain hook that acts as a safer alternative to touching possibly hazardous surfaces.

Team PHS

Portable Handwashing Station

The Interfaith Sanctuary provides food and housing services for the homeless and displaced populations of Boise. Because of the COVID-19 pandemic, hand sanitation has become a high priority for the Sanctuary and is a general need for all of the homeless population. Therefore, the team has been tasked with providing hand sanitation services using upcycled materials and responsible water usage methods to provide the shelter with a durable, low-cost hand washing station that is functional in all seasons. The goal of the product, which will be delivered during Spring 2021, is to provide year-round hand sanitation to the populations served by the Interfaith Sanctuary, but to do so with sustainable methods.

Engineering Plus – Session 2

Session 2: 4:00 – 4:25 PM

Choose a presentation to attend

Team MaskMo

An app to make it fit just right

With the majority of states requiring citizens to wear masks in public, it is important that users find a mask that fits properly and that is comfortable to wear, maximizing the mask’s potential in protecting against the virus. We are creating a mobile application that will help the general public use face masks more effectively during the COVID-19 Pandemic. In addition to the proper fit, the app will help combat users forgetting to grab/ put on a mask when they leave their living spaces. Even with a vaccine, masks will most likely be used for years to come. It is crucial that we develop smart and safe practices now. Our Engineering team this semester will be focusing on developing a mobile app designed to aid users to have a properly fitting protective mask. The app will be able to make recommendations based on the user’s facial features, material preferences, previous discomforts, and existing disabilities. The application will also send reminders to users to wear their masks each time they leave their designated living space.

Team Tactile

Tactile wall with interchangeable tiles

Imagine if you were in third grade and your teacher gave you full access to fidget spinners and any toy you wanted in order to keep focused. For students with a variety of special needs, a tool to manage their anxiety and stress is essential for behavior management in the classroom. We are designing a tactile wall that provides a stress relieving tool for young students in the classroom. This project has been a joint effort between the Engineering Plus program and the College of Education. The goal of this project is to create a research tool for educators to be used in a local special education classroom: a tactile sensory wall. Students from the College of Education will observe the sensory wall in use in order to determine what materials will be most effective in relieving stress in the classroom.