Research Groups

-

Advanced Materials Laboratory

Dr. Brian Jaques

Boise State’s research on materials for extreme environments involves collaborations with the Idaho National Laboratory and many other private and public partners. The work in the AML focuses on the synthesis, processing, and characterization of metals, ceramics, and composites for applications in extreme environments where high temperatures, corrosive gases and/or radiation damage are expected. The AML specializes in advanced technology nuclear fuel developments, in-situ in-pile instrumentation, additive manufacturing, as well as novel materials synthesis techniques.

Boise State’s research on materials for extreme environments involves collaborations with the Idaho National Laboratory and many other private and public partners. The work in the AML focuses on the synthesis, processing, and characterization of metals, ceramics, and composites for applications in extreme environments where high temperatures, corrosive gases and/or radiation damage are expected. The AML specializes in advanced technology nuclear fuel developments, in-situ in-pile instrumentation, additive manufacturing, as well as novel materials synthesis techniques.

-

Advanced Nanomaterials and Manufacturing Lab (ANML)

Dr. Dave Estrada

The ANML is devoted to developing material and manufacturing solutions to address engineering grand challenges. Current research focuses on understanding the unique physical properties of 1-dimensional and 2-dimensional nanomaterials, and translating research in this area to practical applications in energy, water, and healthcare using additive manufacturing techniques.

The ANML is devoted to developing material and manufacturing solutions to address engineering grand challenges. Current research focuses on understanding the unique physical properties of 1-dimensional and 2-dimensional nanomaterials, and translating research in this area to practical applications in energy, water, and healthcare using additive manufacturing techniques.

-

Applied Electrochemistry & Corrosion Lab (AECL)

Dr. Mike Hurley

The research group conducts collaborative academic and industry related research while offering select graduate and undergraduate students an opportunity to learn the science behind corrosion and contribute to engineering solutions. The research is focused on understanding how materials interact with their environment and studying electrochemical degradation (corrosion) at different scales with state-of-the-art techniques.

The research group conducts collaborative academic and industry related research while offering select graduate and undergraduate students an opportunity to learn the science behind corrosion and contribute to engineering solutions. The research is focused on understanding how materials interact with their environment and studying electrochemical degradation (corrosion) at different scales with state-of-the-art techniques.

-

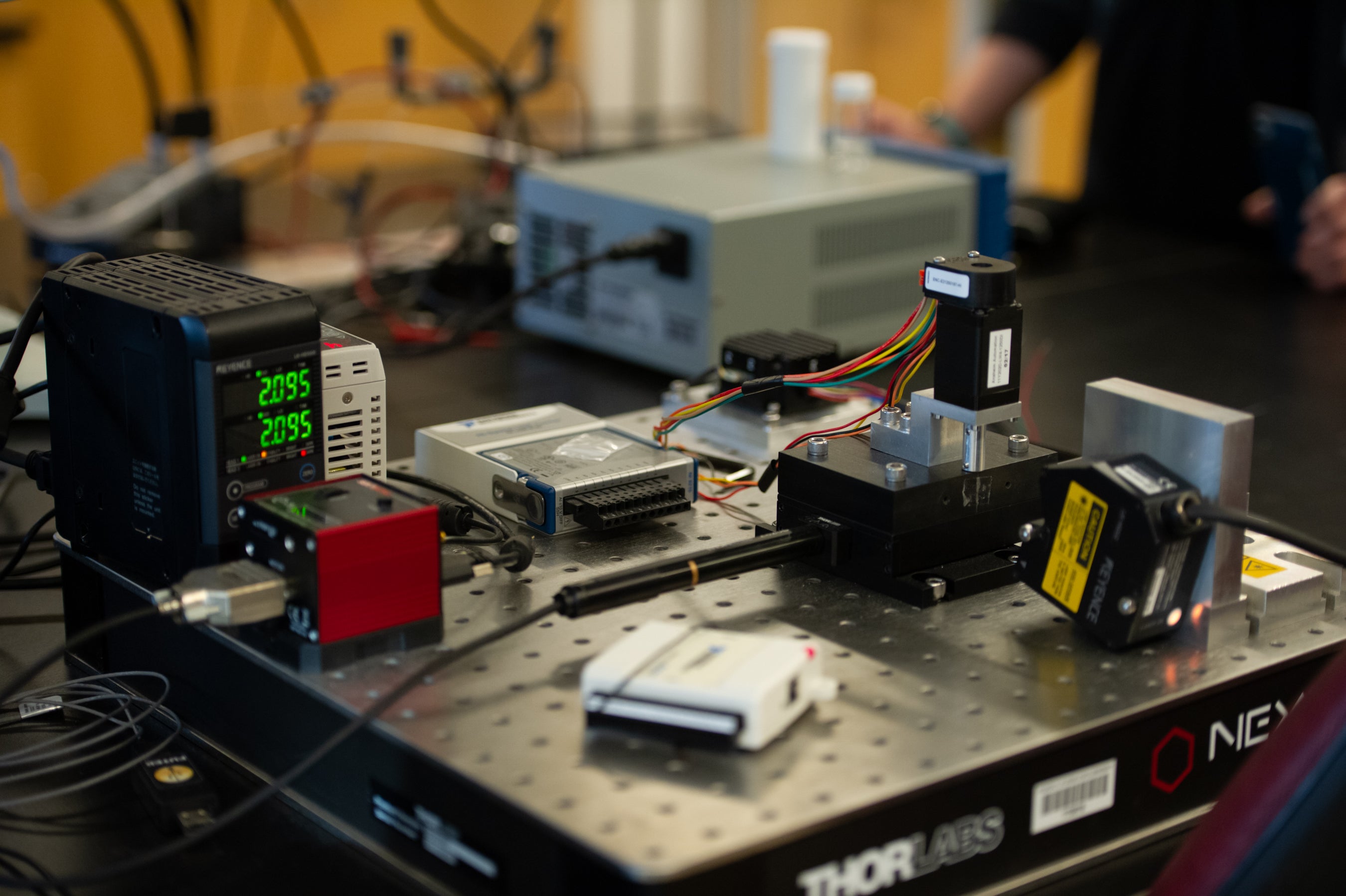

Atomic Films Deposition Lab

Dr. Elton Graugnard

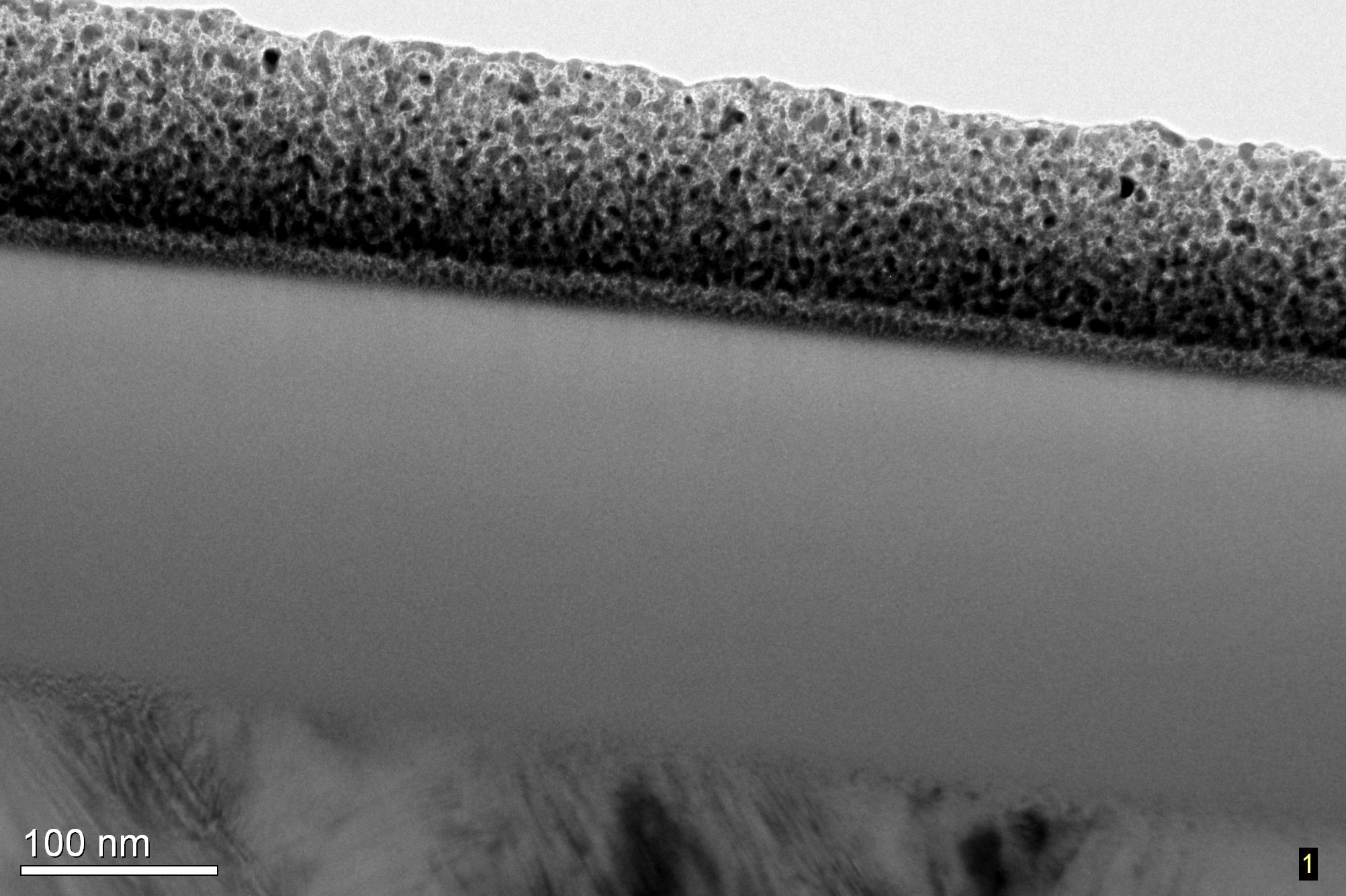

We develop thin film deposition and characterization processes and apply thin film coatings for a range of applications. A key area of our research is in developing atomic layer deposition (ALD) processes for atomically-thin two-dimensional (2D) materials, which may be only a few atoms in thickness. Our interests are in developing new ALD processes for materials with potentially useful properties

We develop thin film deposition and characterization processes and apply thin film coatings for a range of applications. A key area of our research is in developing atomic layer deposition (ALD) processes for atomically-thin two-dimensional (2D) materials, which may be only a few atoms in thickness. Our interests are in developing new ALD processes for materials with potentially useful properties

-

Computational Materials Engineering

Dr. Eric Jankowski

Computer simulations are like a microscope that permits every detail of a material to be observed. Our team develops open source simulation tools that allow supercomputing technologies to be applied to materials problems. Specific focus areas include materials for generating solar power inexpensively, engineering carbon fiber composites, and molecular assemblies at interfaces.

Computer simulations are like a microscope that permits every detail of a material to be observed. Our team develops open source simulation tools that allow supercomputing technologies to be applied to materials problems. Specific focus areas include materials for generating solar power inexpensively, engineering carbon fiber composites, and molecular assemblies at interfaces.

-

Electrochemical Energy Materials Laboratory (EEML)

Dr. Claire Xiong

The EEML is focused on interdisciplinary electrochemistry, materials science and engineering, and interfacial and surface chemistry. Current efforts include work on energy materials for rechargeable batteries (e.g., Li-ion and Na-ion batteries) as well as for nuclear systems through synthesis and advanced characterizations.

The EEML is focused on interdisciplinary electrochemistry, materials science and engineering, and interfacial and surface chemistry. Current efforts include work on energy materials for rechargeable batteries (e.g., Li-ion and Na-ion batteries) as well as for nuclear systems through synthesis and advanced characterizations.

-

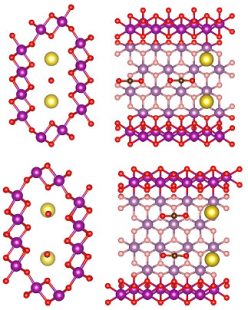

Functional Ceramics Lab

Dr. Rick Ubic

This research group has two focuses. One is the crystallography and structural characterization of functional ceramics including microwave dielectrics, ferroelectrics, and ionic conductors, with a special emphasis on the crystal chemistry of perovskite materials. The second is the structural evolution of nuclear graphite under irradiation and oxidation.

This research group has two focuses. One is the crystallography and structural characterization of functional ceramics including microwave dielectrics, ferroelectrics, and ionic conductors, with a special emphasis on the crystal chemistry of perovskite materials. The second is the structural evolution of nuclear graphite under irradiation and oxidation.

-

Materials Theory & Modeling

Dr. Lan Li

The group focuses on the development and implementation of computational and data-driven methods to capture process-structure-property-performance relationships. Research includes 2D materials for electronic and energy devices, DNA network arrays for quantum computing, nuclear materials and sensor design, and advanced manufacturing technology.

The group focuses on the development and implementation of computational and data-driven methods to capture process-structure-property-performance relationships. Research includes 2D materials for electronic and energy devices, DNA network arrays for quantum computing, nuclear materials and sensor design, and advanced manufacturing technology.

-

Magnetic Materials Lab

Dr. Peter Müllner

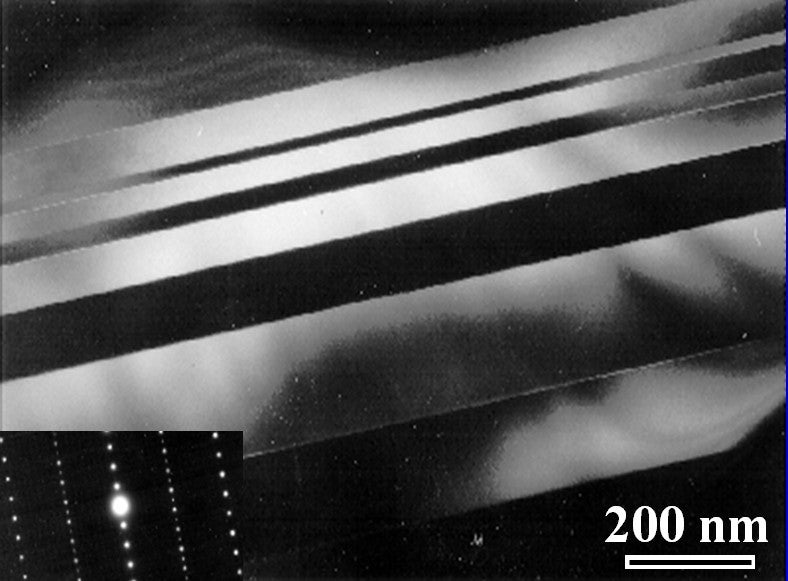

We develop magnetic materials in two areas: (1) Smart materials that bend or change shape in response to magnets. This characteristic enables manufacturers to develop lighter, smaller mechanical devices across a wide range of application areas such as for medical use or space exploration. Our team focuses on Ni-Mn-Ga alloys. We begin by growing bulk single crystals, and conduct experimental studies to address the research span from crystal growth through alloy fabrication and device development. We examine magneto-mechanics across a wide range of materials such as metallic foam, thin films, fibers, and nanostructures. (2) Rare-earth-free magnets for energy applications. Wind turbines require strong magnets, for which only one source exists. Thus, strong magnets are critical for energy sustainability. To mitigate the national vulnerability in this area, we develop manganese based “gap magnets”, which obtain this name by filling the price and property gap between strong and expensive rare-earth magnets and weak and cheap ferrites. We focus on ternary and quaternary Mn-Al-X-Y alloys.

We develop magnetic materials in two areas: (1) Smart materials that bend or change shape in response to magnets. This characteristic enables manufacturers to develop lighter, smaller mechanical devices across a wide range of application areas such as for medical use or space exploration. Our team focuses on Ni-Mn-Ga alloys. We begin by growing bulk single crystals, and conduct experimental studies to address the research span from crystal growth through alloy fabrication and device development. We examine magneto-mechanics across a wide range of materials such as metallic foam, thin films, fibers, and nanostructures. (2) Rare-earth-free magnets for energy applications. Wind turbines require strong magnets, for which only one source exists. Thus, strong magnets are critical for energy sustainability. To mitigate the national vulnerability in this area, we develop manganese based “gap magnets”, which obtain this name by filling the price and property gap between strong and expensive rare-earth magnets and weak and cheap ferrites. We focus on ternary and quaternary Mn-Al-X-Y alloys.

-

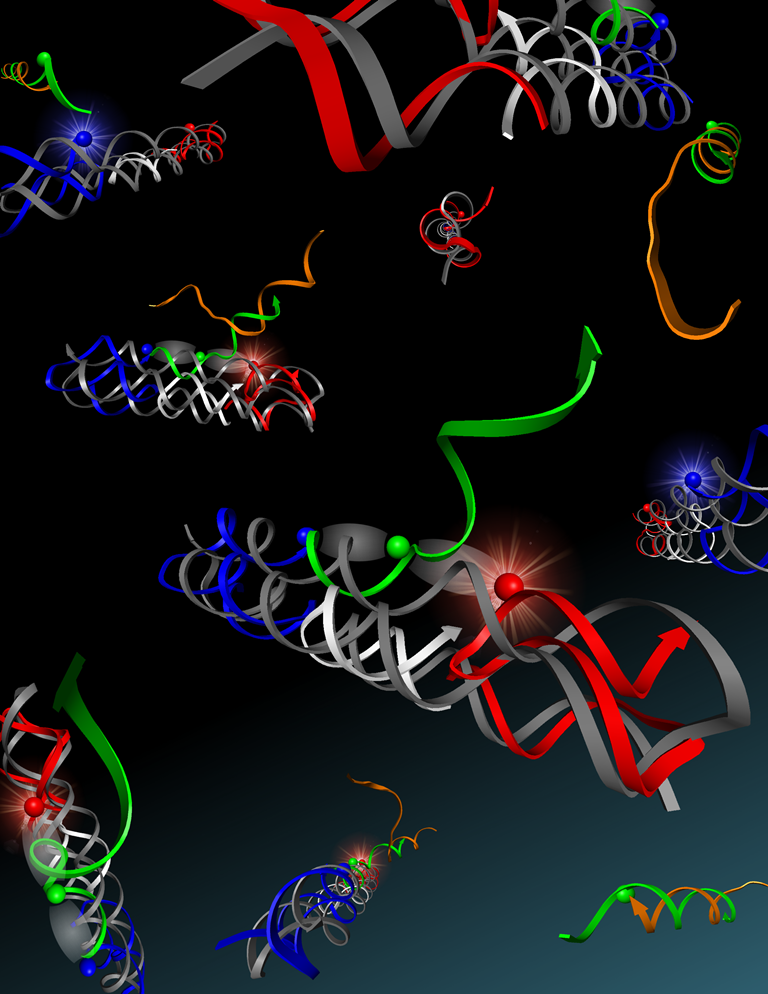

Quantum DNA

Dr. Bill Knowlton, Dr. Jeunghoon Lee, Dr. Ryan Pensack, Dr. Bernie Yurke

The qDNA research area pioneers the use of deoxyribonucleic acid (DNA)—the building block of life on our planet—as a programmable, self-assembling architecture to organize dye molecules for quantum information systems (QIS). In particular, the qDNA research group has shown DNA self-assembly to be a viable platform for arranging and controlling the organization of dye aggregates to enable exciton delocalization.

The qDNA research area pioneers the use of deoxyribonucleic acid (DNA)—the building block of life on our planet—as a programmable, self-assembling architecture to organize dye molecules for quantum information systems (QIS). In particular, the qDNA research group has shown DNA self-assembly to be a viable platform for arranging and controlling the organization of dye aggregates to enable exciton delocalization.