Highlighted Research Contributions

ANML, the Advanced Nanomaterials and Manufacturing Laboratory at Boise State University, takes pride in sharing its publications, each representing a milestone in cutting-edge research and innovation.

Our interdisciplinary team of researchers and collaborators has contributed to leading journals and conferences across various fields, showcasing our commitment to advancing knowledge and addressing real-world challenges.

Recent Publications

-

Tuesday May 27th, 2025

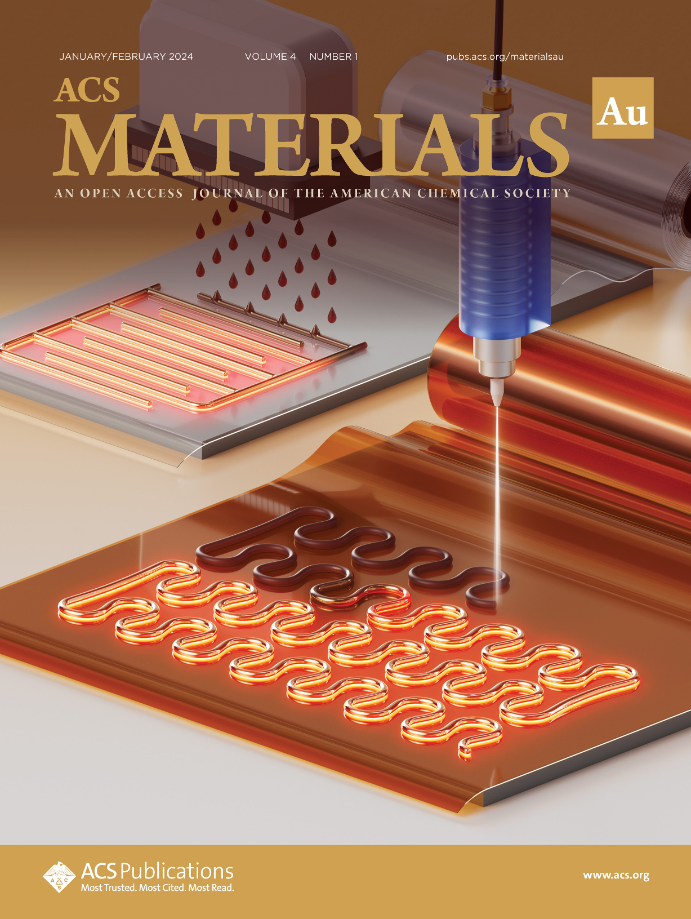

StableTi<sub>3</sub>C<sub>2</sub>T<sub>x</sub> MXene Ink Formulation and High-Resolution Aerosol Jet Printing for High-Performance MXene Supercapacitors

-

Monday May 19th, 2025

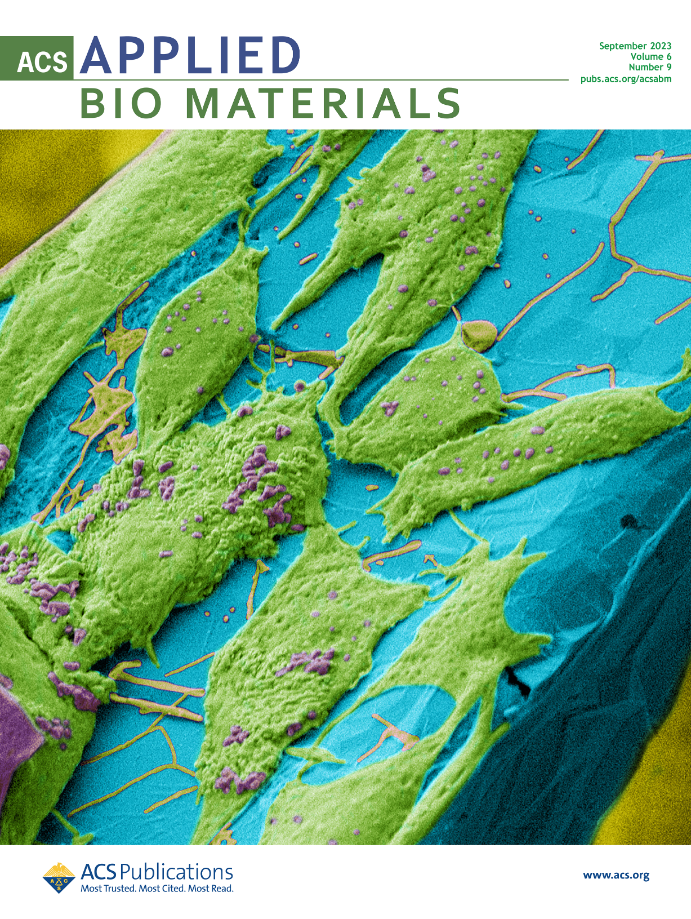

Direct Scaffold-Coupled Electrical Stimulation of Chondrogenic Progenitor Cells through Graphene Foam Bioscaffolds to Control the Mechanical Properties of Graphene Foam-Cell Composites

-

Monday May 5th, 2025

Electroless Plating of Copper on Laser-Induced Graphene for Flexible Hybrid Electronic Applications

-

Thursday Oct 17th, 2024

Nozzle-Free Printing of CNT Electronics Using Laser-Generated Focused Ultrasound

-

Saturday Aug 31st, 2024

Experimental Examination of Additively Manufactured Patterns on Structural Nuclear Materials for Digital Image Correlation Strain Measurements

Publications Archive

Looking for our older publications? Visit our Publications Archive to view documents spanning from 2008-2022.