The Advanced Nanomaterials & Manufacturing Laboratory uses “top-down” and “bottom-up” techniques to synthesize nanoscale building blocks for the co-design of materials, devices, and systems with applications at the nexus of healthcare, energy, and water.

Our Vision & Mission

The vision of the ANML is to be a world leading research group innovating for global impact.

The ANML is devoted to fostering an innovative, transformative, and equitable educational environment that fosters creativity and enables materials and manufacturing solutions for grand engineering challenges which have no regard for political, socioeconomic, or cultural boundaries.

INNOVATION

Using Nanotechnology to Resolve Humanitarian Challenges

It is a widely held belief that nanotechnology and innovations in manufacturing will enable our world to tackle many of the daunting and looming challenges we face, particularly those related to the increasing energy demands and rising healthcare costs of our country and our global society.

Boise State University’s Advanced Nanomaterials and Manufacturing Laboratory strives to establish a diverse and inclusive environment to foster creativity in solving the toughest engineering challenges. We believe research with such important humanitarian implications begins with an appreciation for the many different people and cultures around the world, and a deep understanding of the potential impacts of nanotechnology research on society and the environment.

INDUSTRY SECTORS

The Advanced Nanomaterials and Manufacturing Laboratory (ANML) at Boise State University stands at the forefront of transformative research across vital sectors, including healthcare, energy, manufacturing, and water.

The interdisciplinary approach of ANML in these sectors exemplifies its commitment to advancing science and technology for the betterment of society across diverse and essential domains.

Health Care

- Solid-state nanopores for cancer detection and chemotherapeutics

- Tissue engineering

- Bioprinting

- Neural interfaces

- Flexible hybrid biosensors

- Epidermal electronics

Energy

- Fundamental transport phenomena

- Energy harvesting

- Energy storage

- Energy efficient semiconductors

- In-pile nuclear sensors

Manufacturing

- Nanomaterial ink synthesis

- Materials jetting (AJP, PJP, IJP, EJP)

- Extrusion and screen printing

- Photonic sintering

- Roll-to-roll processing

- Machine learning

- MOCVD/CVD/CVT

Water

- Flow – electrode capacitive deionization

- Ammonia removal from agricultural waste streams

- PFAS/PFOS removal from semiconductor waste streams

- Heavy metal and multi – ion separations

- Novel sensors for water quality monitoring

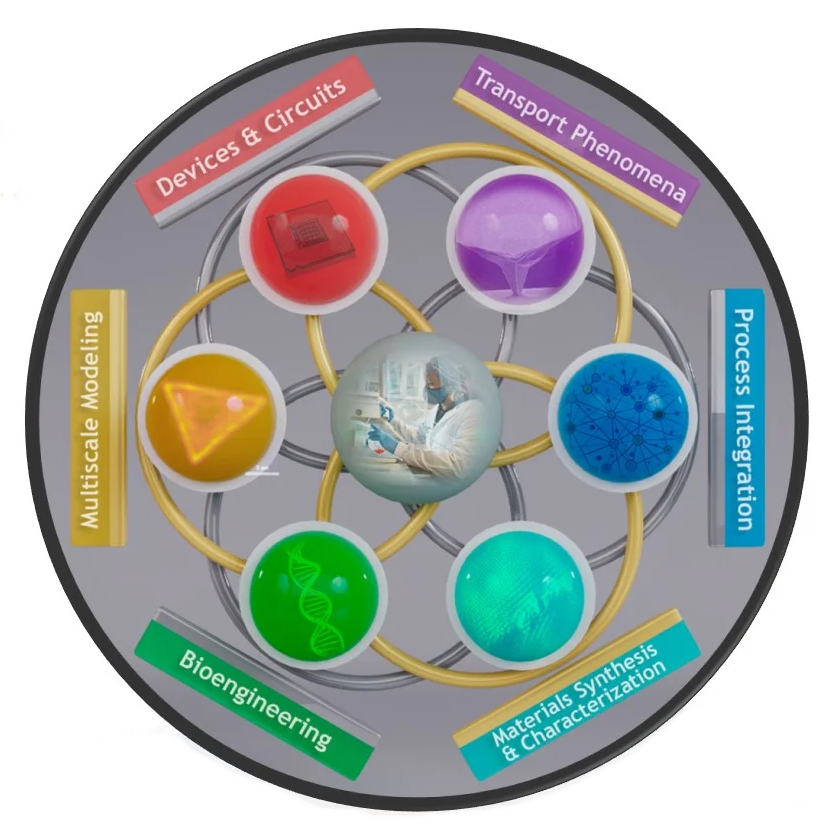

Our Process

We use multi-scale computational modeling and machine learning techniques to enable an Atoms-to-Devices approach in our investigations. We transform these materials into practical devices using compatible and low cost additive manufacturing technology. We are the first university laboratory in the State of Idaho to synthesize truly 2-dimensional (2D) materials, and we now regularly synthesize 2D materials for a variety of applications in Energy, Water, and Healthcare.

Our core facilities include surface and interface science (including X-ray photoelectron spectroscopy, confocal Raman spectroscopy, and a Bruker nanoIR3 AFM-IR w/ s-SNOM and SThM), semiconductor thin films synthesis (AIXTRON 2D CCS MOCVD, CVD, CVT, printing), nanoparticle ink synthesis and characterization, musculoskeletal tissue engineering and bioprinting (CellLink BioX and LumenX, cell culture suite), and electrical and thermal transport (Keithley 4200 SCS and cryogenic chambers). We are continuously seeking opportunities to partner with industry and government in order to accelerate the translation of research to market.