Every aspiring student has their “why” for pursuing higher education. For Timothy (Tim) Phero, one of his primary driving factors was the United Nations (UN) sustainability development goals (SDGs). The UN SDGs outline 17 of the world’s most pressing issues, and a few stood out to Tim: 1) facilitating quality education, 2) promoting responsible production and consumption, and 3) providing access to affordable clean energy. Even though Tim used these goals as defining factors of his academic and professional life, it was not always clear to him how he could contribute towards the SDGs. Then he joined the Advanced Materials Laboratory, where he found a supportive place to establish his roots and began learning how to conduct high impact materials science and engineering research. Tim admits that a graduate degree in materials science and engineering (MSE) was not always on his radar because he completed his undergraduate education in mechanical engineering. However, the multidisciplinary nature of MSE, and his undergraduate background in ME eventually allowed him to become a unique expert in additive manufactured (AM) sensors and instrumentation. His graduate research helped pave the way toward new foundational knowledge about additively manufactured materials and their suitability for nuclear energy applications.

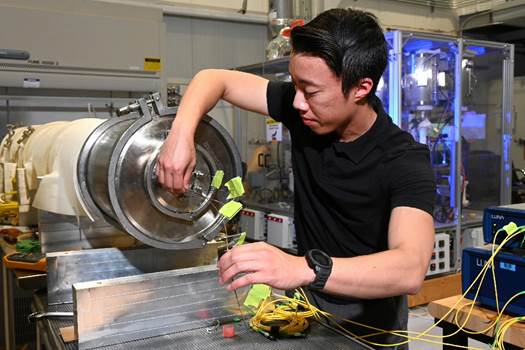

Tim’s research focused on understanding the influence of sensor design, processing, and environment conditions on the microstructure, electrical performance, and reliability of conformally AM printed sensors. While AM techniques have demonstrated the ability to produce functional electronic components, there is a limited understanding of the operational impact, environmental resilience, and robustness of the printed electronics on curved surfaces while in harsh environments. Tim used materials jetting AM techniques to develop, test, and qualify AM mechanical strain sensors and compare them against existing sensing technologies. He developed methods to reliably and repeatedly fabricate AM strain sensors and tested their performance in separate effects (e.g., mechanical strain, high temperature, irradiation, etc.). This increased overall understanding of the structure, properties, and processing on the performance of AM printed systems and accelerates the capabilities of the nuclear industry’s sensors and instrumentation, which provided necessary cost and schedule savings of advanced reactor designs.

This work led to Tim being awarded the Idaho National Laboratory (INL) Graduate Fellowship in 2022 where he continued this work as a Ph.D. student at one of nation’s leading facilities for nuclear energy research. After his graduation in May 2025, Tim plans on using his expertise at the INL where he will continue pursuing his lifelong commitment to help the United States and the world, as a whole, reach a more sustainable future.