Sections

2.0 Responsibilities, Authority and Resources

- 2.1 Chemical and Laboratory Safety (CaLS)

- 2.2 Laboratory Safety Officer (LSO) and Laboratory Safety Specialist

- 2.3 Safety Committees

- 2.4 Department Chair

- 2.5 Principal Investigator

- 2.6 Laboratory Safety Coordinator (LSC)

- 2.7 Laboratory Worker

- 4.1 Hazard Identification Systems (HIS)

- 4.2 Globally Harmonized System (GHS)

- 4.3 NFPA and HMIS systems of Hazard Identification Systems

- 4.4 GHS Aligned Transport Pictograms (DOT, IATA, DGR)

- 4.5 Standard GHS Chemical Container Labelling

- 4.6 Safety Data Sheets (SDS)

- 4.7 Additional Sources of Information

- 4.8 Chemical Inventory Management System

- 4.9 Laboratory Signage

- 5.1 Routes of Entry

- 5.2 Exposure Assessment and Monitoring

- 5.3 Medical Surveillance

- 5.4 Reporting Exposure

- 6.1 Hazard Minimization, Elimination, Substitution, and Reduction (ESR)

- 6.2 Engineering Controls

- 6.3 Administrative Controls

- 6.4 Personal Protective Equipment

Appendix A: Definitions and Abbreviations

1.0 Purpose

Boise State University strives to provide a safe and healthy place for its faculty, staff, students and visitors. The Chemical Hygiene Plan (CHP) serves as guidance for working safely in Boise State laboratories and serves as reference for many federal, state, and local regulatory requirements as well Boise State policies. It by no means covers all regulatory requirements or Boise State policies.

The CHP fulfills the requirements outlined by the Idaho General Safety and Health Standards (IGSHS) 111 – “Laboratories and Chemical Storage Safety Rules”, 29 CFR 1910-1200 – “Hazardous Communication Plan”, and 29 CFR 1910.1450 “Occupational Exposure to Hazardous Chemicals in Laboratories”, which are enforced by the Idaho Division of Occupational and Professional Licenses (IDOPL) and the Occupational Safety and Health Administration (OSHA), respectively.

The purpose of the CHP is to communicate general laboratory safety requirements and will help standardize practices across the University. It provides chemical safety guidance and describes proper practices, procedures, equipment, and facilities for faculty, staff, students, and visitors in Boise State laboratories. This guidance will inform and help protect them from potential physical and health hazards presented by chemicals used in a laboratory and can help minimize exposure or reduce exposure to acceptable levels. It is essential for Principal Investigators, supervisors, laboratory workers, and students to know and adhere to the provisions of this document.

1.1. Scope

The Chemical Hygiene Plan applies to all Boise State University laboratories. Chemical safety for other areas is covered under Chemical Hazard Communication.

1.2. Lab Specific Chemical Hygiene Plan

Laboratories may develop their own chemical hygiene plan or laboratory safety manual, but it must be at least as stringent as all Boise State written programs and comply with all regulatory requirements and Boise State policies. The office of Chemical and Laboratory Safety (CaLS) recommends using the Boise State Chemical Hygiene Plan for the lab as a reference guide and supplementing it with laboratory specific procedures and requirements.

2.0 Responsibilities, Authority and Resources

2.1. Chemical and Laboratory Safety (CaLS)

The mission of Boise State University’s Chemical and Laboratory Safety (CaLS) department, previously known as Environmental Health and Safety, is to assist University colleges and departments in providing a safe and healthful workplace and to assist the University as a whole in maintaining compliance with environmental health and safety regulations and guidelines and University policies. CaLS responsibilities and authority are outlined in Boise State Policy 9140. In regard to the CHP, CaLS:

- Provides expert advice and consultation on environmental health and safety

- Performs workplace evaluations which may include air samples, swipes, or other tests to determine the amount and nature of airborne and/or surface contamination, and to extrapolate personnel exposure levels from that data.

- Develops and provides general safety

- Develops and maintains the Chemical Hygiene Plan and associated university level programs and documents.

- Assists with the selection of engineering controls and personal protective equipment and their proper use.

- Acts as a liaison with regulatory agencies on the local, state, and federal levels, as well as non-regulatory accreditation organizations.

CaLS has the authority to stop any activity which is an immediate danger to the life and health of laboratory workers, employees, students, or the community or an immediate danger to the environment as outlined in Boise State Policy 9140.

2.2 Laboratory Safety Officer (LSO) and Laboratory Safety Specialist (LSS)

The LSO position serves as the University’s Chemical Hygiene Officer and the LSS serves as a chemical hazards advisor, are staff members of CaLS, and is qualified, by training or experience, to provide technical guidance in the development and implementation of the safety and health standards in the CHP. The positions coordinate:

- The evaluation, review, and implementation of the University

- Laboratory safety trainings and assists departments and colleges with meeting training

- The provision of technical expertise to employees regarding laboratory safety and health issues and assistance to University departments, colleges, employees, and students in complying with the CHP.

- The review of hazardous substance labeling, handling, storage, use, spill cleanup, decontamination and disposal, including standard operating procedures (SOPs) dealing with the safe use and disposal of these substances.

- The review, as necessary, of new research protocols prior to initiation to identify the use of hazardous chemicals and assistance to principal investigators in developing proper measures to inform and protect laboratory workers.

- Safety assessments of laboratories and storage areas and recommended follow-up

- Assistance to colleges, departments, safety committees and principal investigators in conducting their own routine assessments.

- The review of the acquisition, operation, and maintenance of fume hoods, emergency safety showers, eyewashes, and fire extinguishers in all laboratories where chemicals are

- The disposal of hazardous waste generated in laboratories in accordance with University policies and written program along with federal, state, and local regulations.

- The investigation of all reports of laboratory hazards incidents, chemical spills, and near- misses to prevent repeat occurrences.

- The maintenance of records to ensure their availability to workers and administrative

- The review and approval of the creation, modification, or closure of

- The investigation of exposure complaints or concerns for referral for medical consultation or performance of exposure monitoring.

2.3. Safety Committees

Safety committees are important bodies in extending the understanding and guidance provided by CaLS across their respective entities. They are responsible for reviewing and providing guidance regarding safe operations of research and teaching laboratories and other facilities. Safety committee representatives are expected to meet on a regular basis to discuss safety issues and provide feedback on policies, programs, and procedures. They ensure that information discussed at the safety committee meetings is communicated to everyone in their labs. Safety committee responsibilities will be outlined in the Laboratory Safety Committee Policy 9240. In regard to the CHP, each safety committee:

- Provides recommendations and assistance with developing safe work practices, Standard Operating Procedures and job hazard analyses for department/college activities, which includes personal protective equipment requirements.

- Develops suitable training documents and protocols as appropriate at the college, department and/or laboratory level.

- Assists with compliance activities for the CHP and additional safety

- Reviews and makes recommendations in response to safety training reports, experimental protocols for hazard identification and safety requirements (as necessary), exposure evaluation requests and reports, availability of facility safety equipment, and emergency

- Assists in conducting and reviewing accident/injury/illness investigations and provides

- Conducts and reviews operations and facility safety assessments on a regular

- Maintain communications with department/college staff, faculty, and students and CaLS concerning the quality of the work environment. This includes indoor air quality, ergonomics, thermal comfort, etc.

- Perform other safety related functions as may be assigned by the Administrative Head, Vice President of Research Administration, or recommended by CaLS.

2.4. Department Chair

The Department Chair shall ensure the CHP and associated programs and policies are followed by personnel under their direction.

The Department Chair must:

- Review compliance and discrepancies in safety performance of the department as necessary, and work toward resolution of such issues to ensure safe practices and techniques are being employed.

- Review accident reports and make recommendations for future procedures or practices that shall minimize the repetition of that type of accident.

2.5. Principal Investigator

For this document, the Principal Investigator (PI) is a faculty or staff member who has overall responsibility for a laboratory and the research/education equipment, practices, procedures and techniques employed in that laboratory. The PI holds the responsibility of ensuring laboratory workers are working in a safe environment. They may designate some or all of the responsibilities to another individual (e.g. laboratory supervisor, laboratory safety coordinator), but the PI is ultimately responsible. The PI must:

- Assure all work under their direction or performed in their laboratory is conducted in accordance with the CHP and other applicable University policies and programs.

- Lead the development of suitable, specific training materials and protocols to allow safe practices for all of the activities within their lab.

- Ensure Laboratory Workers are properly trained and understand procedures applicable to safety in their laboratories and work areas.

- Maintain a current research group roster for easy and rapid communication of emergencies and directed responses of any campus incident.

- Document general and laboratory specific

- Provide adequate engineering controls and personal protective equipment to laboratory workers and ensure their proper use.

- Assign a laboratory safety coordinator to act as a point of contact for CaLS and assist with safety assessments and other laboratory safety related issues.

- Maintain accountability of the research lab chemical inventory and all related safety documentation such as SOPs and SDSs.

- Submit research protocols to CaLS and applicable safety committees, as necessary, for review prior to commencing work.

2.6. Laboratory Safety Coordinator

A Laboratory Safety Coordinator (LSC) should be assigned to each research and teaching laboratory to act as a point of contact for CaLS and Laboratory Workers regarding safety issues and assessments.

An LSC may be any laboratory worker associated with the laboratory including the PI. It is a best practice to have the LSC conduct laboratory safety self-assessments on a regular basis.

2.7. Laboratory Worker

A Laboratory Worker is any faculty member, staff member, or student performing or supervising work in a Boise State laboratory, this includes PIs and department lab managers. A Laboratory Worker is subject to the CHP and all its provisions and is responsible for following it. A Laboratory Worker must:

- Complete, understand and follow all laboratory safety-related policies, programs, procedures, and training received.

- Ensure that all supervisees have completed, understand and follow all laboratory safety- related policies, programs, procedures, and training, CaLS and lab-specific.

- Know the physical and health hazards, handling procedures, and emergency response information for the chemicals or tasks they are handling or performing.

- Understand the function and proper use of engineering

- Follow the established dress code for working in a lab.

- Understand the function and proper use of all personal protective equipment (PPE) and wear required PPE as necessary.

- Promptly report all work-related incidents, injuries, and illnesses to CaLS and their supervisor. Near misses, potential serious safety issues, and danger of environmental contamination must also be reported.

- Contact the LSC, PI, safety committee, or CaLS for further clarification if any of the above items are not clearly understood.

3.0 Training Requirements

All laboratory workers must read and understand the CHP and complete all required safety training. Applicable safety training must be completed prior to beginning any laboratory work.

It is the PI’s responsibility to determine training requirements for their laboratory workers based upon their roles and activities in the lab and ensuring its successful completion. CaLS can assist with determining training requirements. CaLS may require additional training based upon their assessment.

3.1. General Laboratory Safety Training

The general laboratory safety training focuses on materials relevant to University laboratories in regard to University safety policies, programs, and procedures along with regulatory requirements. The training provides general knowledge pertaining to laboratory hazards and controls to minimize exposure. (mandatory)

3.1.1. Computer Based

Computer based training consists of web-based modules covering various safety topics. Each college, department, and laboratory have a default level of modules which must be completed initially and annually. Additional modules may be required based upon the type of work each individual laboratory worker may conduct. Modules cover a broad range of topics such as biosafety, ethidium bromide, hazardous waste, compressed gases, and electrical safety. Assigned training modules must be completed annually.

3.1.2. Classroom

Classroom based laboratory safety training is conducted by CaLS. The training covers:

- Chemical Hygiene Plan (this document)

- Brief overview of lab safety regulations

- Hazard Communication (globally harmonized system, chemical identification and information)

- Safe handling practices and use of engineering controls

- Personal protective equipment (PPE)

- Disposal of hazardous chemicals

- Emergency equipment location and operation

- Emergency response procedures

Sessions are typically held near the beginning of each semester including the summer session. Contact CaLS for upcoming classroom training sessions. Laboratory Workers must attend the next available session after becoming a Laboratory Worker. Laboratory Workers should discuss refresher frequency with their supervisor.

3.1.3. Additional Training

Laboratory Workers may be required to attend additional training based upon the work they conduct. The training frequency will be determined by the PI and CaLS and must consider associated regulatory requirements.

CaLS can develop and perform additional training more specific to a group’s needs. Please contact CaLS for details.

3.2. Laboratory Specific Training

The PI is responsible for providing Laboratory Workers with safety instruction and information that is specific to their lab and associated tasks, and should include the review of laboratory standard operating procedures. The training may include knowledge-based training and skill-based assessments.

The PI must also identify hazardous procedures or tasks not covered in this document and inform laboratory workers of these hazards present in the lab. This information and instruction must be documented by the PI as job-specific training. Training documentation must be available for review by CaLS.

Safety instruction for the use of chemicals must satisfy the hazard awareness requirements listed below.

- The name of the chemical and its hazardous component(s);

- The health and physical risk(s) associated with the chemical;

- Signs of release and symptoms of exposure;

- How and when to use engineering controls and personal protective equipment;

- Labeling and storage requirements;

- Disposal procedures;

- Emergency procedures for spills and exposures; and

- Laboratory specific operating procedures

CaLS can assist laboratories in providing this training during a staff meeting, by appointment, or other convenient time.

Laboratory specific training must be completed prior to beginning work. Refresher training must be done periodically as determined by the PI.

3.2.1. New Laboratory Workers

A Laboratory Worker new to a laboratory must be given an overview of the hazards and activities associated with the laboratory along with pertinent safety and emergency response information and procedures. The New Laboratory Worker Safety Checklist or an equivalent tool must be used for documentation.

3.3. Training Records

Responsibility falls upon the PI to maintain documentation for general and laboratory specific training. Documentation is essential to prove a laboratory worker was properly trained regarding the hazards and processes in their laboratory. Without documentation, a laboratory worker is not considered properly trained.

4.0 Hazards Identification

4.1. Hazards Identification Systems (HIS)

Per OSHA, one of the “root causes” of workplace injuries, illnesses, and incidents is the failure to identify or recognize hazards that are present, or that could have been anticipated. The HIS described in this section are a process of evaluating whether a situation or thing has the potential to cause harm, such as illness or injury. This process is often linked to risk assessment, and involves analyzing and evaluating the risks associated with a hazard, and then implementing ways to control or eliminate it as well as communicating to any associated personnel the nature of the hazards. There are four general HIS used on campus and they each give slightly different information or are intended for specific circumstances. A critical element of any effective safety and health program is a proactive, ongoing process to identify and assess such hazards.

To identify and assess hazards, employers and workers:

- Collect and review information about the hazards present or likely to be present in the workplace.

- Conduct initial and periodic workplace inspections of the workplace to identify new or recurring hazards.

- Investigate injuries, illnesses, incidents, and close calls/near misses to determine the underlying hazards, their causes, and safety and health program shortcomings.

- Group similar incidents and identify trends in injuries, illnesses, and hazards reported.

- Consider hazards associated with emergency or nonroutine situations.

- Determine the severity and likelihood of incidents that could result for each hazard identified, and use this information to prioritize corrective actions.

4.1.1. GHS, NFPA, HMIS, DOT/IATA, and BSU Hazard Placard Iconography and Signage

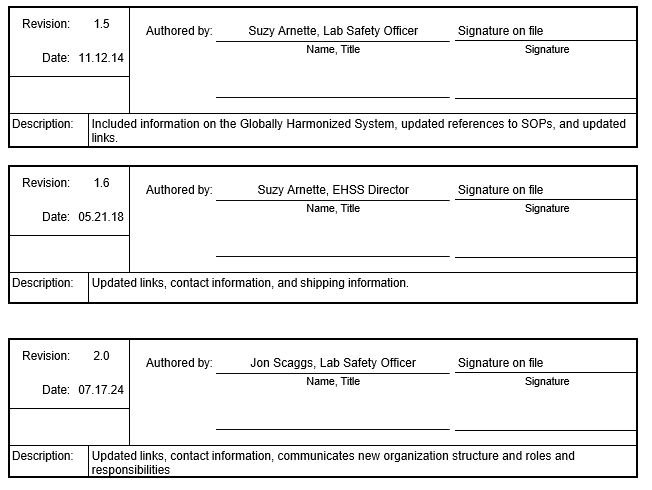

There are four general HIS used on campus and they each give slightly different information or are intended for specific circumstances. The GHS icons are typically the standard for laboratories to describe hazardous materials and will be used in the chemical inventory management system, in SOP’s, and for hazardous waste processes. The Non-GHS aligned icons used by the National Fire Prevention Alliance (NFPA) and HMIS systems are still valid as described in OSHA HAZCOM 2012 but the GHS pictograms and classifications are still recommended.

4.2. Globally Harmonized System (GHS)

The Globally Harmonized System of the Classification and Labelling of Chemicals (GHS) is a set of guidelines for ensuring the safe production, transport, handling, use and disposal of hazardous materials. It was adopted by the United States in March 2012.

GHS is meant to be a logical and comprehensive approach to:

- Defining health, physical and environmental hazards of chemicals (although environmental hazards are outside OSHA’s jurisdiction)

- Creating classification processes that use available data on chemicals for comparison with the defined hazard criteria

- Communicating hazard information in a prescribed and uniform way on labels and safety data sheets

- The nine standard GHS pictograms can be seen in figure 4.1

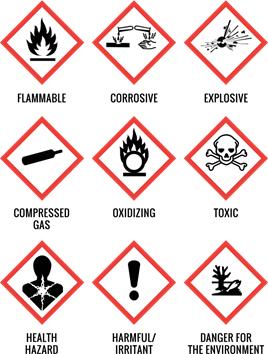

4.3. NFPA and HMIS Systems of Hazard Identification

The NFPA diamond, also known as the Fire Diamond or NFPA Hazard Diamond, is a label that helps workers identify hazardous materials and the severity of their hazards. NFPA 704, Standard System for the Identification of the Hazards of Materials for Emergency Response, specifies the identification requirements for these materials. NFPA 704 applies when another Federal, state or local regulation or code requires its use. NFPA 704 does not specify when a container, tank or facility must be labeled rather it specifies how to label when another code, standard or an AHJ (Authority Having Jurisdiction, such as the local fire department) requires such labeling. The standard applies to industrial, commercial, and institutional facilities that manufacture, process, use, or store hazardous materials. It does not apply to transportation, use by the general public, and a few other specific uses.

The purpose of the standard is to provide a simple, readily recognized, and easily understood system of markings that provides a general idea of the hazards of a material and the severity of the hazards as they relate to emergency response. The identification system specified in NFPA 704 is intended to enable first responders to easily decide whether to evacuate the area or to commence emergency control procedures and to also provide information to assist in selecting firefighting tactics and emergency procedures.

The Hazardous Materials Identification System (HMIS) is a proprietary numerical hazard rating that incorporates the use of labels with color bars developed by the American Coatings Association as a compliance aid for the OSHA HazCom Standard. The name and abbreviation is a trademark of the American Coatings Association. While using either of the two NFPA or HMIS to identify hazardous material information, the GHS system is preferred. There is no reason you cannot display either the GHS pictographs or classification in addition to the NFPA or HMIS information.

4.4. GHS Aligned Transport hazard pictograms (DOT, IATA, and DGR)

The GHS transport pictograms are the same as those recommended in the UN Recommendations on the Transport of Dangerous Goods, widely implemented in national regulations such as the U.S. Federal Hazardous Materials Transportation Act (49 U.S.C. 5101–5128) and D.O.T. regulations at 49 C.F.R. 100–185. Both the DOT and IATA (international Air Transport Association) also use the DGR (Dangerous Goods Regulations) in combination with the GHS classifications to categorize and communicate hazards in shipping. By definition (OSHA), hazardous materials are those dangerous goods, any substances or materials, that are capable of posing “an unreasonable risk to health, safety, and property when transported in commerce.” They must be identified with proper packaging, communication, handling, and storage to reduce the associated risks to people, populations, and the environment during transportation. The 49 CFR regulations of hazardous materials then, apply to all modes of transportation be it air, rail, highway, or waterway, and the proper labeling, description, storage, and transportation of materials. All hazardous materials must have the GHS aligned transport pictograms clearly and prominently displayed on external packaging. The pictograms that are used on the outside of the packages containing hazards can be seen below in Figure 4.3.

4.4.1. Non-GHS Aligned Transport pictograms

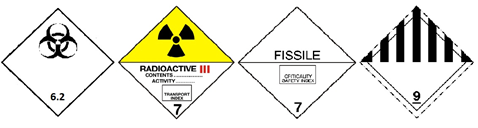

The following pictograms seen in Figure 4.4 are included in the UN Model Regulations but have not been incorporated into the GHS because of the nature of the hazards. They may be required on packages due to other AHJ regulations. These include infections materials, radiological materials, and miscellaneous dangerous materials.

Unlike the other 8 hazardous classes that specifically define a hazard such as explosives for Class 1, flammable and combustible liquids for Class 3, toxic and infectious substances for Class 6, as examples, Class 9 only vaguely defines a potential hazard or dangerous good. It describes any miscellaneous hazardous material that “presents a hazard during transportation,” but doesn’t fall under any other hazard class. In other words, any materials that are listed in hazard classes 1 through 8 cannot be listed as a Class 9 hazardous material. It also broadens the definition of some materials that would not otherwise be classified as hazardous.

While Class 1 through Class 8 specifically defines the hazards they present in the way of combustion, corrosion, toxins, lethality, radioactivity, and so forth, Class 9 has been purposefully left vague. In many ways, metaphorically at least, Class 9 is the “catch all” of hazardous material classifications. At first look, it offers examples that relate to material properties. Materials that have an anesthetic, noxious or other similar property which could cause extreme annoyance or discomfort to a transport professionals to the extent that it might interfere or prevent them from carrying out their assigned duties. There is some potential for this category to be misused and its for materials that don’t clearly fit into the other categories.

The second part of the definition of Class 9 is those materials that are hazardous substances or wastes and marine pollutants; and any “elevated temperature materials.” Elevated temperature materials apply to liquids at a temperature at or above 100 °C (212 °F) or a liquid phase material with a flashpoint at or above 38 °C (100 °F) that is intentionally heated or a solid phase material at a temperature at or above 240 °C (464 °F).

Some common examples of category 9 materials are ammonium nitrate fertilizers, asbestos, aviation regulated liquid, automobile airbags, battery-powered equipment, carbon dioxide, solid or dry ice, chemical kits, first aid kits, lithium batteries, and magnetized materials. This is not a comprehensive list of materials in this category.

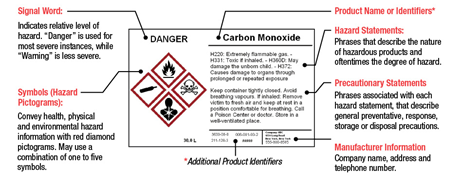

4.5 Standard GHS Chemical Container Labeling

A chemical container label is the primary means for communicating the contents of a container and its hazard(s). Every container, including those containing water and working containers, must be labeled to ensure employees and students are aware of the contents. The basic requirements for a GHS approved label from a manufacturer of distributer can be seen in figure 4.5.

4.5.1. Original Container

Chemicals in original vendor containers must have labels indicating the chemical or product name and the vendor’s name. The GHS hazard warning symbols must be prominently visible on the labels.

4.5.2. Laboratory Container

All containers of chemicals decanted from an original container or prepared in the laboratory must be labeled with the chemical or product name(s), concentration(s), and primary hazard(s) using the appropriate GHS symbol. It should also be dated and include the responsible worker’s name. This includes containers of reaction products or byproducts, as well as separation processes such as distillations and extractions.

4.5.3. Expiration Date

Time sensitive chemicals (e.g. peroxide formers) must be labeled with an appropriate expiration date.

4.5.4. Pipe/Tubing Carrying Hazardous Materials

Pipes or tubing carrying a hazardous material from a source that is not readily apparent or in proximity to other pipes or tubing must be labeled. Warning signs along the course of the pipe or tubing may also be warranted. For example, a pipe carrying analytical gas from a compressed gas cylinder to another area should be labeled in several places along its length.

4.5.5. Waste Containers

All containers of chemical waste must be labeled as outlined in the Hazardous Waste Management Manual. A current copy of the HWMM must be available in the laboratory’s safety manual.

4.5.3. SDS Retention and Access

Each laboratory must maintain a SDS for every chemical compound or product, and every supplier of that compound or product, used in the lab – both current AND past use for a minimum of 30 years. For example, a laboratory using bleach from two suppliers must have a bleach SDS from each supplier. Each laboratory must also maintain those SDSs replaced by an updated version. Past or out-of-date SDSs may be stored out of the work area if the laboratory implements a procedure for accessing them.

Current SDSs must be readily accessible to all laboratory workers and emergency responders and located near the main laboratory exit or outside the laboratory in a non-laboratory area. At the present time, a SDS may be kept electronically or as a hard copy, but both must be readily accessible.

4.6. Safety Data Sheets (SDS)

A SDS is a document prepared by a supplier to summarize the health and safety information associated with a product. Suppliers are required to provide an SDS for each chemical they make or offer. Following the OSHA adoption of the GHS in 2012, each SDS must follow a standardized format and contain the following 16 sections:

- Section 1. Identification

- Section 2. Hazard(s) identification

- Section 3. Composition/information on ingredients

- Section 4. First-aid measures

- Section 5. Fire-fighting measures

- Section 6. Accidental release measures

- Section 7. Handling and storage

- Section 8. Exposure controls/ personal protection

- Section 9. Physical and chemical properties

- Section 10. Stability and reactivity

- Section 11. Toxicological information

- Section 12. Ecologicial information

- Section 13. Disposal considerations

- Section 14. Transport information

- Section 15. Regulatory information

- Section 16. Other information, including date of preparation or last revision

As of June 1, 2015, all SDSs provided by manufacturers must be in the GHS standard format.

4.6.1. SDS Retention and Access

Each laboratory must maintain a SDS for every chemical compound or product, and every supplier of that compound or product, used in the lab – both current AND past use for a minimum of 30 years. For example, a laboratory using bleach from two suppliers must have a bleach SDS from each supplier. Each laboratory must also maintain those SDSs replaced by an updated version. Past or out-of-date SDSs may be stored out of the work area if the laboratory implements a procedure for accessing them.

Current SDSs must be readily accessible to all laboratory workers and emergency responders and located near the main laboratory exit or outside the laboratory in a non-laboratory area. At the present time, a SDS may be kept electronically or as a hard copy, but both must be readily accessible.

4.6.2. Obtaining a SDS

Manufacturers and suppliers of chemical compounds and products are required to provide a SDS for every product they offer. A SDS typically accompanies a chemical shipment or is mailed separately. Companies may be contacted via telephone or written request to obtain one, but many make their SDSs available online or they may be requested via their websites. CaLS can also assist in obtaining a SDS.

4.7. Additional Sources of Information

The Chemical Hygiene Plan serves as a limited resource for information on specific chemicals, chemical hazard classes, and additional hazards. Detailed information is available for some specific topics as a Standard Operating Procedure (SOP). Contact CaLS to suggest additional topics or request additional information.

4.7.1. SOP’s in the laboratory

For all new procedures and materials an SOP is required before the ascribed work can begin or chemical purchases allowed. The SOP will contain a risk analysis for the new materials and processes including mitigation strategies. There is a template for the SOP on the CaLS website.

4.7.2. Laboratory Safety Manual

All active labs should maintain lab safety manual which will reinforce the CHP but be specific for the processes and materials for each lab. There is a template for the Lab safety manual on the CaLS website.

4.7.3. CaLS website and Chemical Manufacturers Websites

The Boise State CaLS website contains information pertaining to chemical safety including links, written programs, training, and contact information for additional assistance.

Manufacturers may also have additional information available in regards to chemical safety.

Reference materials offer a wide range of topics and information. Many are available through the library and CaLS.

4.8. UNHCems Chemical Inventory System

A current chemical inventory of the laboratory is necessary to inform Laboratory Workers of the current stock and potential hazards present in the area. It is also needed by emergency responders in case of a fire, chemical spill, or other incident. Each laboratory must maintain a current chemical inventory in the UNHCems system. The inventory must be broken down by individual container and include:

- Unabbreviated chemical or product name

- Manufacturer

- Chemical Abstract Service (CAS) Registry number

- Only required for chemical names

- Container size

- Number of containers

- Container Owner / PI

- Date inventory performed

- Person who conducted inventory

- Storage location

Contact CaLS to schedule your initial inventory and to receive training on the UNHCems system or obtain barcodes.

Once the initial inventory has been completed by CaLS, an inventory reconciliation will be performed on an annual basis.

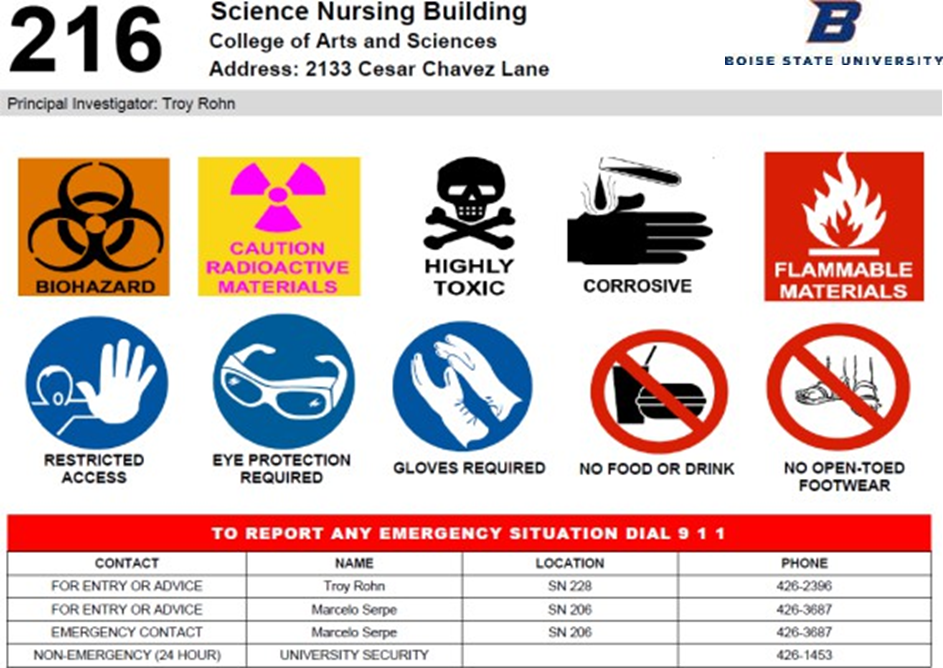

4.9. Laboratory Signage

4.9.1. Laboratory Safety Signage

Laboratories must have signage posted on or near the door that clearly identifies potential laboratory hazards and entry requirements. They are to remind laboratory staff and inform visitors of this information and aid the fire department or other emergency responders. The signage must also include the lab’s emergency contact information, principal investigator, room number, and physical address. It may include general contact information as well.

CaLS works with the laboratories to update signage on a regular basis. Laboratories must notify CaLS of changes in laboratory hazards, entry requirements, and emergency contacts. The Laboratory Safety Signage Form is available on the CaLS website.

An explanation of the symbols found on all BSU lab HAZPLACARD is available on the Boise State CaLS website or by contacting CaLS.

4.9.2. Emergency Contact List

An emergency contact list must also be posted near laboratory telephones and on or near the laboratory door. The contacts must include applicable laboratory and college/department contacts, emergency response numbers, Security, and CaLS. An emergency contact template is available on the CaLS website. The template includes links to chemical manufacturers and technical information for spill response.

4.9.3 Safety Signage

Signage must be conspicuously posted indicating locating of eyewashes and safety showers. Signage is strongly recommended for fire blankets, fire extinguishers, spill kits, and any other safety equipment to identify its location. The signage must identify the equipment by name or an appropriate symbol.

Each laboratory sink must be posted with a sign indicating “Non-potable water” or similar language.

Contact your building coordinator or CaLS for assistance in locating sources for this type of signage and its installation.

5.0 Occupational Toxicology

5.1. Routes of Entry

To evaluate the risks of adverse health effects from chemicals, one must be aware of the routes of entry into the body, duration of exposure, toxicity of the chemical, exposure limits, and odor threshold of the chemical. This section explains these principles and describes how to reduce chemical exposure.

5.1.1. Inhalation

Inhalation is the most frequent route of chemical exposure in the lab. Exposure by this route can produce poisoning by absorption through the mucous membrane of the nasal passage, mouth, throat, and lungs and can seriously damage these tissues. Inhaled gases or vapors may pass rapidly into the capillaries of the lungs and be carried into the circulatory system. Exposure can be minimized by keeping containers closed when not in use, proper storage of containers, and the use of engineering controls (e.g. fume hood). Respiratory protection may be necessary if engineering controls cannot be used or do not provide sufficient protection. Respirators must not to be used in any area without prior approval by CaLS.

5.1.2. Skin and Eye Contact

Contact with the skin is the second most frequent route of chemical exposure. A common result of skin contact is localized irritation. Many materials are absorbed through the skin quickly and may cause systemic poisoning. The main routes of entry for chemicals through the skin are the hair follicles, sebaceous glands, sweat glands, and cuts or abrasions of the outer layers of the skin. The follicles and the glands are abundantly supplied with blood vessels, which facilitate the absorption of many chemicals.

Skin and eye contact with chemicals can be avoided by the use of appropriate personal protective equipment.

5.1.3. Ingestion

Many of the chemicals used in the lab are extremely dangerous if they enter the mouth and are swallowed. In addition, many chemicals may damage the tissues of the mouth, nose, throat, lungs, and gastrointestinal tract producing systemic poisoning if absorbed through these tissues. To prevent entry of chemicals into the mouth, lab workers should wear gloves and wash their hands immediately after use of any chemical substance and before leaving the lab. Do not store or consume food and drinks in the lab. Mouth pipetting is strictly prohibited.

5.1.4. Injection

Exposure to chemicals by injection seldom occurs in the lab. However, it can inadvertently occur through mechanical injury from glass or metal contaminated with chemicals or when chemicals are handled in syringes. Use proper sharps handling practices. Broken glass or spilled sharps must be collected using mechanical means (e.g. broom and dustpan) and never with one’s hands. Do not re-sheath used needles.

5.2. Exposure Assessment and Monitoring

CaLS may be required to perform an exposure assessment of some laboratory work. An exposure assessment takes into consideration any hazardous materials in use, the task being performed, the work environment including engineering controls, administrative controls, and personal protective equipment. Monitoring may be necessary to assess exposure levels to these hazards.

Laboratory workers should contact their supervisor or CaLS to discuss exposure concerns and request an assessment.

5.2.1. Exposure Limits

Exposure limits have been established to reduce exposure to “acceptable” levels. OSHA and IDOPL set regulatory exposure limits called permissible exposure limits (PEL). The American

Conference of Governmental Industrial Hygienists (ACGIH) has developed recommended exposure limits called Threshold Limit Values (TLVs).

5.2.2. Frequency

Initial monitoring will be performed if there is reason to believe exposure levels for a substance could exceed the action level or permissible exposure limit. Monitoring may be necessary due to equipment or process changes.

Periodic monitoring will be performed if the initial monitoring exceeds applicable action limits or permissible exposure limits. Monitoring frequency will be established by CaLS and based upon the exposure level (current and previous monitoring) and any requirements outlined in applicable standard.

Monitoring may be terminated in accordance with the applicable standard.

5.2.3. Records

Laboratory workers will be notified of monitoring results in writing within 15 days after receipt of any laboratory results either individually or by posting in an appropriate location.

CaLS and the CHO shall maintain records in accordance with the record keeping requirements of applicable OSHA and IDOPL standards.

5.3. Medical Surveillance

Medical consultation or examination shall be offered under the following circumstances:

- A lab worker develops signs or symptoms potentially associated with a hazardous chemical, which they may have been exposed to in the laboratory.

- Exposure monitoring reveals an exposure level above OSHA or IDOPL action limits or permissible exposure limits where the applicable standard requires such medical

- An event occurs such as a chemical spill, leak, or explosion that results in the likelihood of a hazardous exposure.

- A lab worker is exposed to blood or other bodily fluids by a needle-stick, cut, or splash in the face.

5.4. Reporting Exposure

A Laboratory Worker who believes they have had an exposure should contact their supervisor and CaLS for evaluation. The worker or supervisor must contact the Office of Risk Management and Insurance to determine required documentation to be submitted.

6.0 Controlling Hazards

6.1. Hazard Minimization, Elimination, Substitution, and Reduction (ESR)

6.1.1. Hazard Minimization

Using smaller quantities of hazardous chemicals or substituting a less hazardous chemical reduces the risk of serious exposure or spill. See the Hazardous Waste Management Manual for additional waste reduction information. Consider the following possibilities:

- Substitute less hazardous chemicals

- Work on a smaller scale

- Order only what is needed

- Share chemicals when possible

- Utilize the CaLS “Thor Store” for purchasing amounts of common solvents needed instead of buying materials from a vendor.

6.2. Engineering Controls

Engineering controls eliminate or minimize exposure by removing a hazard or acting as barrier between a hazard and a worker. Engineering controls are typically more effective controlling hazards than administrative controls practices or personal protective equipment. They often require a higher cost initially; however, they may be more cost-effective in the long run. Engineering controls range in complexity and cost from something as simple as a sharps container to minimize needlesticks to an interlocking mechanism of an x-ray unit to minimize radiation exposure. In a laboratory, they are often used to minimize contact with a hazard due to chemical splash, explosion, or inhalation.

6.2.1. Local Exhaust Ventilation

Local exhaust ventilation is an engineering control used to reduce inhalation exposure. Common laboratory examples include glove boxes, extraction arms (snorkels), and fume hoods.

6.2.1.1. Glove Box

Glove boxes are complete enclosures used to perform work in an isolated environment. A controllable environment may be necessary to control worker exposure or to protect the chemical itself (i.e. an inert atmosphere). Gloves secured to ports allow manipulation inside the unit. Depending on the type of work being conducted, the following may be required:

- Integrity testing – unit and gloves

- Sensor calibration

- Training

- Usage logs are recommended

- Standard operating procedures Contact CaLS for additional

6.2.1.2. Biosafety Cabinet

Biosafety cabinets (BSC) are used to control exposure to biological aerosols and protect work materials from contamination utilizing a High Efficiency Particulate Air (HEPA) filter. HEPA filters do not capture chemical vapors. A BSC where the filtered exhaust is returned to the laboratory cannot be used for procedures involving flammable liquids, volatile toxic or odorous chemicals. Open flames should not be used in a BSC. Most, if not all, of the BSCs on campus exhaust filtered air back into the laboratory. BSCs are certified annually by an approved vendor. A BSC must be certified when installed and/or moved, including moves of short distances. Decontamination must be carried out if a BSC is to be moved or decommissioned. Additional information is available through CaLS. Certification, maintenance, and HEPA repairs and changeouts can be done through the CaLS office by appointment.

6.2.1.3. Extraction Arm (Snorkel)

Extraction arms or snorkels are typically constructed of flexible ducting and connected to the exhaust ventilation system. They are useful for capturing vapors, fumes, and dust at the source of generation, and work well when designed properly for a given process and have an adequate flow rate. They are typically ineffective for any source beyond a distance of one half the ducting’s diameter (approximately 2-3 inches). Design or modification must be approved by CaLS, Facilities Operations and Maintenance (FOM) and Architecture and Engineering Services (AES).

6.2.1.4. Fume Hood

The fume hood is the most common method of controlling inhalation exposures to hazardous substances in the laboratory. They are useful against fumes and vapors. Their use is recommended whenever handling hazardous materials and may be required to reduce exposure to levels below applicable exposure limits. One needs to consider the chemicals and quantities used for during a process. Processes that generator a dust or particulates need to include a dust collection method. Spray painting is not allowed in a fume hood and must be done in a properly designed spray booth.

6.2.1.5. Alarm

Some fume hoods are equipped with a low-flow alarm. The alarm is an indication the face velocity may be inadequate and not providing proper protection. Contact FOM and CaLS with any issues. Do not tape or deactivate the alarm silence button down, please contact CaLS if the alarm continues to sound.

6.2.1.6. Baffle Controls

Some fume hoods are equipped with controls to adjust the baffles. Baffle adjustment is used to alter the airflow in the hood to better capture and remove air contaminants based upon the work in progress. Most uses involve the baffles opened equal amounts to capture materials released in the hood. However there are occasions where adjustment is beneficial. The use of a volatile low density chemical, hot plate or Bunsen burner may cause contaminants to rise quickly making the lower baffle rather ineffective. High density materials may result in contaminants gathering near the surface of the fume hood making the upper baffle ineffective. There are varying styles and types of baffle controls so it is important to be familiar with the hood used.

6.2.1.7. Emergency Shut Off

Some buildings are equipped with emergency shut offs for the fume hood exhaust system and differ from the alarm and purge controls mentioned above. The emergency shut offs are only to be used by FOM or the fire department.

6.2.1.8. Certification and Maintenance

Fume hoods certification is maintained by CaLS and completed on an annual basis as indicated by a sticker on the fume hood. The sticker is typically found on the side of the sash indicating the height at which it was certified.

The certification process ensures the fume hood is functioning properly and maintains a minimum face velocity measured at the sash threshold of 80 feet per minute.

The grill at the bottom of the sash threshold must be kept clear and should be inspected regularly by the laboratory. The slot should be cleaned if necessary.

Any suspected fume hood malfunctions or issues must be reported to FOM and CaLS. Alterations must be coordinated and approved by FOM and CaLS. Any repair, relocation, or alteration requires recertification of the fume hood by CaLS.

6.2.1.9. Minimizing Materials in the Fume Hood

In order for a fume hood to operate properly, adequate airflow is essential. An easy way to accomplish this is by minimizing the number and size of materials in a fume hood. Materials, such as large equipment, supplies or chemical containers, cannot be used in a fume hood if it prevents the fume hood from functioning properly. The most common issue stems from blocking the lower baffle, which reduces adequate flow at the sash and can disrupt airflow patterns. It may be possible to elevate the materials to maintain flow to the lower baffle. For large equipment, it is generally more effective to install a specially designed enclosure so the chemical fume hood can be used for its intended purpose. Contact CaLS for assistance and assessment.

6.2.1.10. Sash Height

When working at the chemical fume hood, open the sash only as far as necessary to access the work area. The lowered sash helps contain contaminates in the hood and the smaller hood opening makes the hood less susceptible to room drafts and other external air disturbances. Sashes open too high can result an inadequate face velocity reducing its effectiveness. The certification sticker indicates the height at which it was tested and is the maximum working height.

When a fume hood is not in use, the sash should be lowered to within a few inches of the bench or air foil.

The sash can also help protect against splashes or projectiles from chemical spills or explosions. A lowered sash does not eliminate the necessity for appropriate personal protective equipment.

6.2.1.11. Additional Work Practices

- Work at least six inches behind the sash

- Never put your head (or face) inside an operating chemical fume hood to check on an

- Move slowly in and around fume Also be aware opening/closing doors can disturb the airflow.

- Do not stand or sit inside any fume hood

- Any time a fume hood requires maintenance it must be cleared of hazards and cleaned so FOM or contracted technicians are safe to work in or on the hood.

6.2.1.12. Perchloric Acid Use

Perchloric acid must be used in a specifically designed and dedicated fume hood with a wash down system due to potential formation and build up of explosive perchloric acid salts. The fume hood cannot be used for any other purpose especially organic chemicals. Please contact CaLS for additional information.

6.3. Administrative Controls

Administrative controls mainly consist of policies, programs, training, and procedures which guide work and practices to reduce exposure by limiting duration, frequency and/or severity.

6.3.1. Written Documents

Written policies, programs, and procedures are used to document and communicate requirements and responsibilities. The University uses policies to outline high level objectives, responsibilities, and requirements. For example, Boise State Policy 9140 outlines the University’s commitment to environmental health and safety and responsibilities of the University community. Programs, such as the CHP, provide guidance on specific topics typically applying to multiple departments which help guide compliance with University policy and regulatory requirements. Standard operating procedures communicate specific hazards, steps and requirements for equipment, processes and procedures.

6.3.1.1. Laboratory Specific Operating Procedures

Laboratories must establish and maintain operating procedures for equipment, processes, or procedures involving hazardous activities or materials. They are used to:

- Communicate to the Laboratory Worker the potential hazards, required hazard controls, and steps to complete a task safely and correctly.

- Satisfy regulatory requirements to document required engineering controls and personal protective equipment.

- Train laboratory workers in proper procedures making results more consistent between laboratory workers.

The need for a procedure is situation/risk dependent and final determination falls to the PI or Lab Supervisor.

Operating procedures must be part of Laboratory Specific Training and training/review must be documented.

Laboratories should use the Standard Operating Procedure (SOP) template provided by CaLS.

6.3.1.2. Standard Operating Procedure (SOP)

CaLS developed a template for labs to use in order to communicate laboratory hazards, safety information, and operating procedures. The form should be used to communicate and share information regarding broad safety topics to specific equipment procedures. These documents should be completed for all hazardous processes and certain hazardous materials. They should be reviewed periodically to make sure they remain relevant.

6.3.1.3. CaLS Use

CaLS develops SOPs for hazards, processes, and procedures applicable to multiple laboratories or departments or the campus as a whole. They provide general guidance and information relating to potential hazards, exposure controls, handling requirements, and proper procedures for a given topic.

6.3.1.4. College, Department, & Laboratory Use

A college, department, or laboratory may adopt an SOP as their own operating procedure if it fits their specific process, or they can modify it to conform to their specific need. They may also use the template to develop their procedure.

6.3.1.5. SOP Sharing

The idea behind the SOP is not only to communicate hazard and procedure information, but to allow the sharing of this information across colleges, departments, and laboratories. This could create efficiencies and some standardization within Boise State, a college, or department for certain hazards, operations or equipment use. CaLS established a repository of SOPs to facilitate sharing and collaboration. It is not required to post SOPs to the site, but it is encouraged. Please contact CaLS for information on sharing SOPs.

6.3.2. Work Practices

The information in this section applies to the majority of laboratory work or work areas. Information regarding specific chemicals, chemical hazard classes, and additional hazards may be available as an SOP.

6.3.2.1. Prepare for Work with Hazardous Chemicals

- Take the time to read and familiarize yourself with the Chemical Hygiene Plan and its appendices before handling any hazardous chemical.

- Read the Hazardous Waste Management Manual, which contains information covering safe and proper disposal of hazardous chemicals.

- Read applicable laboratory protocols or standard operating procedures, which should outline requirements for handling hazardous chemicals.

- Know the nearest location of all safety equipment as well as the building’s evacuation routes and meeting location.

- Be familiar with the spill and exposure response procedures in the Chemical Hygiene Plan and the Emergency Response Plan – Appendix B (or similar information) located within the lab.

- Become familiar with the health and physical hazards of the chemicals you will be

- For extremely hazardous chemicals or procedures, consider performing a “dry” run with a supervisor to familiarize you with the steps.

6.3.2.2. Minimize Routine Exposure

The following are general work practices designed to minimize exposure from routine work procedures:

- Work involving hazardous chemicals should be conducted in a chemical fume hood whenever possible.

- Do not smell chemicals to determine their

- Never place your head inside of a chemical fume hood to check on an

- Change gloves

- Inspect gloves for tears, cracks, discoloration, and holes before and during

- Release of toxic chemicals or asphyxiants (e.g. chloroform, dry ice, nitrogen) in environmental rooms must be Air is recirculated in these rooms which may lead to a buildup of toxic materials or an oxygen deficient environment.

- Exhaust of an apparatus that may discharge toxic chemicals should be vented into a chemical fume hood, exhaust ventilation system, or filter.

- Storing, handling, or consuming food or beverages in laboratories, storage areas, refrigerators, environmental rooms, or laboratory glassware is prohibited.

6.3.2.3. Personal Hygiene

Personal hygiene in the laboratory can minimize exposure to hazardous chemicals. Some general guidelines for personal hygiene in the laboratory include:

- No eating, drinking, smoking, or applying cosmetics is allowed in laboratory areas. The use of contact lenses in the laboratory should be avoided in laboratory areas.

- Mouth pipetting of any substance is

- Hands must always be washed before leaving the laboratory. Solvents must never be used to wash hands.

- Required, appropriate personal protective equipment (PPE) (e.g. lab coat, eye protection, gloves) must be worn in the laboratory whenever there is a potential for exposure to chemical or physical Please refer to laboratory specific requirements. Guidance for establishing PPE requirements is available by contacting CaLS.

- PPE must not be worn in public areas such as bathrooms, offices, conference rooms, eating areas, and outdoors.

- Gloves must not be worn while touching doorknobs, light switches, telephones, or other common items unless required by the laboratory. Appropriate signage must indicate the PPE requirement.

6.3.2.4. Housekeeping

General guidelines for good housekeeping include:

- Areas around emergency equipment, showers, eyewashes, and exits must be kept

- Areas around all circuit panels must be kept

- All aisles, hallways, and stairs must be kept

- All work areas should be kept clear of

- All chemicals should be returned to their proper storage area at the end of the

- Spills must be cleaned up

6.3.2.5. Transportation and Shipping

Transportation of hazardous materials between campus buildings and off campus must be approved by CALS. This includes, but is not limited to transportation via vehicle, cart, or person. Prior approval is required to ensure proper containment is used, and for transportation on or across a public thoroughfare, Department of Transportation (DOT) hazardous material shipping requirements must be met which may necessitate shipping papers, special labeling, packaging, placarding, or vehicle requirements.

The shipment and receipt of hazardous materials to and from Boise State are regulated by both DOT and International Air Travel Association (IATA). General awareness training is provided for those receiving packages. CaLS is certified to ship hazardous materials for the campus. Training modules are available for specific materials, such as dry ice.

CaLS is responsible for removing hazardous chemical waste from all research laboratories. Hazardous chemical waste procedures are outlined in the Hazardous Waste Management Manual.

6.3.3. Laboratory Safety Assessments

CALS conducts laboratory safety assessments of academic and research laboratories on an annual basis. It is a tool used to help Boise State and its laboratories maintain compliance – both with regulatory requirements and Boise State policies and programs. It covers common laboratory requirements focusing on areas such as:

- Chemical safety

- Hazardous waste

- Training documentation

- Personal protective equipment

- Emergency and safety information

- Emergency equipment

- Fire and life safety

- Engineering controls

A copy of the Laboratory Safety Assessment form is available on the CaLS website.

CaLS does its best to coordinate a time to conduct the assessment with the laboratory safety coordinator or principal investigator. CaLS may perform surprise assessments as deemed necessary.

6.4. Personal Protective Equipment

Personal protective equipment (PPE) is worn to minimize exposure to potential hazards and must be worn when handling hazardous materials or performing potential hazardous activities in the laboratory. Appropriate PPE is based upon the potential hazards and risks associated with those hazards. Hazards and risks can be associated with the chemicals in use, quantities, and where and how they are used. They can stem from temperatures, pressures, or mechanical action applied to a material.

Eliminating unnecessary processes and substances must be the first method used to control hazards. Engineering controls (e.g. chemical fume hood) and administrative controls can be used to control hazards minimizing required PPE.

The PI for each laboratory, with the aid of CaLS, is responsible for determining PPE requirements. PPE requirements must be documented by the laboratory in the form of either job hazard analysis or standard operating procedure.

The PI must ensure appropriate types and sizes of PPE are readily available, laboratory workers are properly trained in regard to use and maintenance, and laboratory workers comply with PPE requirements.

Workers and visitors must comply with laboratory PPE requirements.

Common laboratory PPE is discussed below. Keep in mind different or additional PPE may be required based upon the hazards and associated risks.

6.4.1. Hand and Forearm

6.4.1.1. Gloves

Gloves are required when handling hazardous chemicals or for protection from physical hazards such as against cuts, extreme temperatures, and abrasion. There is no glove currently available that will protect against all chemicals for all types of tasks. Many glove manufacturers have charts

available to help determine the most appropriate glove material. Gloves come in a variety of materials, thicknesses, and cuff lengths. Glove selection must consider the chemicals in use, potential contact time, splash/splatter potential, and dexterity needs.

It is recommended to change thin disposable gloves once they become contaminated or on a regular interval. In some applications, thicker gloves may be reused, but they must be inspected regularly for nicks, punctures, other damage or signs of degradation and discarded when necessary.

Lab workers must remove at least one glove before leaving the immediate work site to prevent contamination of public areas (e.g., doorknobs, light switches, telephones, etc.).

6.4.1.2. Latex Allergy

Latex (i.e., several protein antigens) has been shown to be a sensitizer to some individuals. Sensitization occurs over time with increased symptoms. Exposure to the latex protein is greatly increased through the use of powdered latex. The use of powdered latex is highly discouraged. If a powdered glove is desired, a powdered nitrile glove is recommended.

6.4.1.3. Tyvek® sleeves

Tyvek sleeves provide greater forearm protection than a lab coat. Uncoated sleeves are fluid resistant and coated sleeves provide increased fluid protection. The sleeves must be worn over a lab coat or paired with other necessary body protection.

6.4.2. Body

Body protection may be necessary to protect against chemical splash/splatter or particulate which could cause injury or contamination of an individual or their clothing. It may also be necessary to protect a work area from outside contamination (e.g. clean room).

6.4.2.1. Lab Coat

A long-sleeved laboratory coat must be worn whenever infectious, chemical, or radioactive hazards exist assuming a similar or more protective level of PPE is not required. A lab coat, though not impervious, provides some protection against contact and contamination. Tyvek lab coats or coveralls may also be a suitable option and may offer added convenience since they are disposable.

Contaminated lab coats must be immediately removed and laundered or disposed of properly. Laundering must be done through a commercial laundry service. Home laundering is prohibited. Contact CaLS for available commercial services. It is recommended to not wear lab coats outside of the lab unless transporting hazardous materials between labs.

6.4.2.2. Chemical Resistant Apron

Some chemicals or activities may require protection beyond a lab coat’s capabilities due to splash/spatter potential and the hazardous chemical properties. It is important to select an apron compatible with the chemical in use and an appropriate thickness for adequate protection.

6.4.3. Eyes/Face Protection

The most common types of eye and face protection consist of safety glasses, safety goggles, and face shields. Each serve their own purpose, but all of them must meet requirements outlined in American National Standards Institute (ANSI) Z87.1. “Z87” must be imprinted on the equipment indicating it meets proper specifications.

6.4.3.1. Safety Glasses

Safety glasses must be worn, at a minimum, when handling small quantities of hazardous materials or where there is the potential of flying particulate. They must have side shields for added protection. They are adequate for handling small quantities of moderately hazardous materials with limited splash/spatter potential or materials of low hazard and flying particulate.

Regular prescription glasses do not meet the Z87.1 requirements. Over-the-glasses (OTG) safety glasses are available which fit over most prescription lenses and frames. A number of retailers offer prescription safety glasses. The frames are marked with Z87 and are fitted with polycarbonate lenses. Side shields are required and typically snap on the bows.

Visitors must wear safety glasses while work is underway in the laboratory. Visitors closely observing or participating in processes must wear all required PPE for the process.

6.4.3.2. Safety Goggles

Safety goggles must be worn when handling liquid hazardous materials with a reasonable potential for splash/spatter, injurious materials, or concentrated corrosives. Goggles fit tightly to the face minimizing liquid and vapor contacting the eye area. Vented and non-vented models are available. Vented goggles have some slits/holes, which reduce fogging but increases contact potential. Vented goggles may have direct or indirect venting. Direct venting models may be used for flying particulates, but are not recommended for chemical protection. Non-vented goggles fog easier but provide greater protection. An anti-fog coating is an important feature. Most prescription glasses fit under standard safety goggles.

Goggles provide better protection against large amounts of particulate compared to safety glasses.

6.4.4. Face Shield

A face shield helps protect the users face from splashes and flying particulate. A face shield is only considered supplementary eye protection so safety glasses or goggles must also be worn.

6.4.5. Leg and Foot

Laboratories should consider requiring leg protection such as pants or similar clothing when handling hazardous chemicals to minimize chemical contact with exposed skin. Leg protection must be required when handling corrosive or highly toxic liquids. Leg protection beyond regular clothing may be required for protection from hazards such as molten metal, heat, and cutting hazards.

Foot protection requirements must be based upon the hazards and potential exposure in each lab. Due to the materials being handled in most labs, closed toe shoes (covering the top and sides of the feet) are required. Additional foot protection may be required such as steel toe, leather, or slip-resistant shoes.

6.4.6. Respiratory Protection

Respirator use requires training, medical clearance, and fit testing. Respirators are not to be used in any area without prior approval of CaLS. Contact CaLS for additional information.

6.4.7. Additional Considerations

Additional or a different type of PPE may be necessary dependent upon the laboratory and associated activities. It is recommended laboratories designate minimum PPE for entry to work areas.

Contaminated PPE must be decontaminated or properly disposed. Contaminated PPE may require classification as hazardous waste. Please refer to the Hazardous Waste Management Manual or contact CaLS.

7.0 Emergency Response

The University outlines its emergency response policy and procedures in the Emergency Response Plan which includes Appendix B – Emergency Response Instructions. Emergency responders can be reached by dialing 911 or contacting Public Safety at 426-6911. These numbers must be posted near a laboratory phone and on the corridor door.

All emergency response activities must be reported to your supervisor and CaLS.

7.1. Emergency Equipment

In any emergency, it is critical that all staff members are familiar with the use and location of all emergency equipment. This includes fire extinguishers, fire alarms, safety showers, eyewash stations, first aid kits, and chemical spill kits.

The laboratory must maintain adequate clearance around emergency equipment to allow easy access and proper operation.

All emergency equipment should be on a preventive maintenance schedule. Fire alarms are tested periodically, and extinguishers are inspected monthly. CaLS tests safety showers and eyewash stations monthly unless laboratories have arranged for self-testing. Laboratories should activate their eyewashes on a weekly basis. If available, first aid kits must be properly equipped with unexpired supplies based upon occupancy.

7.2. Seeking Medical Treatment

7.2.1. 911

911 should be contacted for a serious medical emergency. If you are unsure of the seriousness of the situation, make the call. If emergency responders are deemed necessary, they will respond to the scene and assess the situation.

7.2.2. Emergency Room or Additional Care

7.2.2.1. Faculty Member, Staff Member, or Student Employee

A faculty member, staff member, or student employee requiring medical attention where emergency responders or their transport are not necessary should seek care through one of St Luke’s Occupational Health Clinics or St Luke’s Emergency Room.

7.2.2.2. Students

Students should seek medical attention as determined by coverage of their insurance provider. Depending on the provider, students may be able to seek medical attention from the University Health Services.

7.3. Chemical Exposure

The treatment of a chemical exposure takes precedent over spill cleanup, spill containment, or property damage including water damage from the use of an eyewash or safety shower.

If possible, obtain assistance to remove contaminated PPE and clothing and contact emergency responders if necessary.

Laboratories are recommended to have a set of scrubs or other such clothing in case a laboratory worker’s clothes become contaminated.

Refer to Section 5.4 Reporting Exposure for reporting requirements.

7.3.1. Eye Contact

Eyes must be promptly flushed with water using an eyewash for 15 minutes following contact with any chemicals. The eyes should be held open as much as possible. Medical help should be sought immediately after flushing.

7.3.2. Skin Contact

The affected areas must be immediately flushed with water for 15 minutes. Once the flushing has started, contaminated PPE and clothing must be removed. Medical attention should be sought immediately after flushing.

7.3.3. Inhalation/Ingestion

Immediately contact emergency responders for guidance.

7.3.4. Contaminated Sharps Injury

The affected areas must be immediately flushed with water for 15 minutes. Once the flushing has started, contaminated PPE and clothing must be removed. Medical attention should be sought immediately after flushing.

7.4. Chemical Spill

7.4.1. Small Spill

A small spill is defined as a spill less than or equal to 200mL or 200 g and not of an extremely hazardous substance AND within the cleaning capabilities and comfort level of the laboratory and Laboratory Workers.

If you are not sure or uncomfortable with the clean-up, contact your supervisor and CaLS for assistance.

- Inform others in the area of the

- Turn off any gas burners without putting yourself in harm’s

- Retrieve SDS without putting yourself in harm’s

- Review applicable SDS and determine controls, PPE, and need for

- Put on necessary protective clothing (gloves, safety goggles or glasses, and lab coat).

- Cover small spills with absorbent

- Clean spill area working from outside toward the

- Rinse spill area with

- Label and retain spill materials for

- Contact your supervisor and CaLS and complete a Spill Investigation

7.4.2. Large Spill

A large spill is a spill greater than 200mL or 200 g OR any amount of an extremely hazardous substance OR beyond the cleaning capabilities or comfort level of the laboratory or Laboratory Workers.

- Inform others in the area of the

- Turn off any gas burners without putting yourself in harm’s

- Retrieve SDS without putting yourself in harm’s

- Evacuate the

- Close doors behind

- If deemed necessary or unsure of severity, immediately call You may also pull a fire alarm.

- Contact your supervisor and then call CaLS at 426-3906 and Public Safety at 426-

- Post warning outside the area and lock doors if possible to prevent re-

- Complete a Spill Investigation Report.

7.4.3. Spill Kit

Laboratories must have chemical spill kits available suited to the chemicals and quantities in their particular laboratories. Basic supplies should consist of appropriate absorbents, equipment, and PPE. A basic supply list is available on the CaLS website. If necessary, contact CaLS for assistance determining adequate supplies. Custom spill kits can be requested through the Thor Store.

8.0 Chemical Storage

Chemicals must be stored in an appropriate manner to ensure safety in the laboratory. Proper storage:

- Protects flammables from ignition and heat,

- Minimizes the potential of exposure to toxic materials, and

- Segregates incompatible materials to prevent accidental mixing due to a spill, poor housekeeping, earthquake, fire, etc.

8.1. General Storage Guidelines

The following are guidelines for appropriate chemical storage:

- Incompatible chemicals must be Contact CaLS for assistance.

- Hazardous materials must not be stored above eye

- Shelving used for chemical storage must have vertical

- Liquids may not be stored above eye level even if they are not hazardous

- Chemicals must be stored in compatible

- Containers must be securely

- Hazardous liquids must be stored in secondary

- Containers of time-sensitive chemicals (e.g. peroxide formers) which result in an increased risk must be dated upon receipt, again upon opening and tested on an annual There are standard labels available for this purpose if needed. Contact CaLS for these labels

- Refrigerators or freezers used for flammable liquid storage must be designed and rated for flammable liquid storage.

- Flammable liquids and volatile toxic materials must not be stored in cold

- Flammable liquid storage outside of a flammables cabinet must be less than or equal to 10 gallons.

- Class 1 Flammable liquids must be stored in safety cans single container’s quantity is greater than one gallon.

- Chemical storage under and near sinks is restricted to bleach and compatible cleaning

- Chemical storage areas must be clearly labeled with hazard information (e.g. flammable cabinet must be labeled “flammable” or similar).

- Compressed gas cylinders must be properly stored and secured. Reference applicable

8.2. Expired Chemicals

Any expired or out-of-date chemical must be properly disposed if it presents an increased safety risk over time such as peroxide formers and picric acid. The PI may choose to retain chemicals past their expiration if the chemical has no increased risk and it is properly stored. CaLS strongly recommends disposal of expired chemicals if it is not needed in the foreseeable future.

8.2.1. Time-Sensitive Expired Chemical Disposal

Failure to dispose of time sensitive chemicals prior to their expiration date can result in increased disposal difficulty and cost. Depending on the chemical and its age, testing and disposal by an outside vendor may be required. In extreme cases, an explosive ordinance disposal unit (i.e. bomb squad) may be required. Costs associated with the testing and disposal of time-sensitive chemicals beyond their expiration date may be the responsibility of the laboratory and its department.

8.3. Specific Storage Requirements

Specific chemical storage requirements and segregation guidelines are necessary for the different hazard classes. Please contact CaLS with any questions or concerns.

8.4. Security

Security measures must be in place to prevent theft or unauthorized use of hazardous materials. These materials must be stored in a secure location when no authorized person is present in the area. Examples include a locked cabinet or locked room door. In most instances a single barrier is sufficient; however, some materials may require additional barriers (i.e. locked cabinet in a locked room). Lab doors should remain closed at all times to prevent unauthorized personnel from access. This will protect lab personnel, hazardous materials, theft, and sensitive or intellectual property.

Appendix A: Definitions and Abbreviations

American Conference of Governmental Industrial Hygienists (ACGIH)

The American Conference of Governmental Industrial Hygienists (ACGIH) is a professional association of industrial hygienists and practitioners of related professions. One of its goals is to advance worker protection by providing timely, objective, scientific information to occupational and environmental health professionals

Anesthetics/Narcotics

Anesthetics/narcotics depress the central nervous system. Many solvents (chloroform, ether) have an anesthetic effect.

Asphyxiants

Asphyxiants interfere with oxygen and/or availability and include the following: